Complete Guide to James Hardie Fire Wall Systems in New Zealand

Complete Guide to James Hardie Fire Wall Systems in New Zealand – Ensuring building safety against fire is a non-negotiable aspect of modern construction in New Zealand. The New Zealand Building Code (NZBC) sets stringent requirements for fire resistance to protect lives and property. Meeting these standards requires robust, tested, and reliable building materials designed specifically for this purpose.

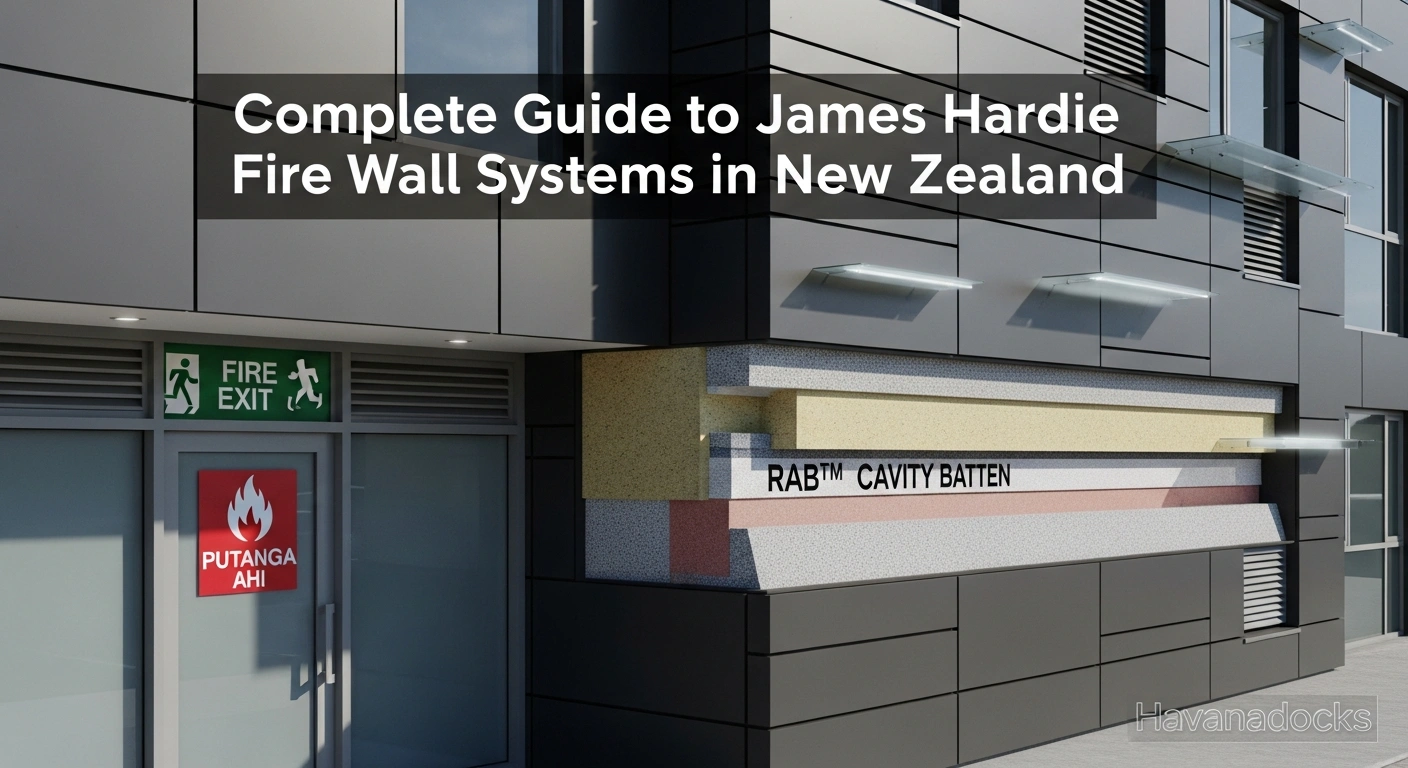

Among the leading solutions available, James Hardie provides a comprehensive range of fire-rated wall systems. These systems are engineered to contain fire and slow its spread, providing critical time for evacuation and emergency response. This guide offers an in-depth look at the james hardie fire rated wall system nz, covering its components, applications, and compliance requirements.

Understanding Fire Resistance Ratings (FRRs) in New Zealand

A Fire Resistance Rating, or FRR, is a crucial performance metric for building elements in New Zealand. It quantifies how long a specific wall, floor, or ceiling system can withstand a fire under test conditions. The rating is expressed in minutes and comprises three key criteria.

The criteria are Stability, Integrity, and Insulation, often shown as a series of numbers like 60/60/60. Stability refers to the system’s ability to maintain its structural load-bearing capacity during a fire. Integrity is its capacity to prevent the passage of flames and hot gases to the non-fire side.

Insulation measures the system’s ability to limit the temperature rise on the non-exposed surface. A complete james hardie fire rated wall system nz is designed and tested to achieve specific ratings for all three of these criteria. These ratings are essential for compliance with Clause C of the New Zealand Building Code.

The Core Components of a James Hardie Fire Rated Wall System NZ

A common misconception is that fire resistance comes from a single board or product. In reality, it is the complete, tested assembly that provides the specified fire rating. A james hardie fire rated wall system nz is a synergistic combination of several key components working together.

The foundation of these systems is James Hardie’s advanced fibre cement technology. Fibre cement sheets are non-combustible and are designed to withstand high temperatures without losing their structural integrity. This inherent fire resistance forms the basis of the entire wall assembly’s performance.

The performance of the system is critically dependent on every element being correctly specified and installed. This includes the framing, insulation, fasteners, and even the jointing compounds and sealants. Each component plays a vital role in achieving the required Fire Resistance Rating.

Framing: The Structural Backbone

The structural frame, whether it is timber or light-gauge steel, forms the backbone of the wall. The type and size of the framing material directly influence the overall FRR of the system. Each james hardie fire rated wall system nz has been rigorously tested with specific framing configurations.

Steel framing and timber framing behave differently under fire conditions, requiring distinct system designs. For example, steel framing can lose strength at high temperatures, while timber framing forms a protective char layer. James Hardie provides detailed specifications for both framing types to ensure predictable and reliable fire performance.

Adherence to the specified stud sizes, centres, and fixing methods is absolutely critical. Any deviation from the tested configuration can compromise the fire rating and lead to non-compliance. Architects and builders must consult the James Hardie Fire and Acoustic Design Manual for precise framing details.

Insulation: Managing Heat Transfer

Insulation is a critical component for achieving the ‘Insulation’ part of a Fire Resistance Rating. While fibre cement provides integrity, specific types of insulation are required to control heat transfer through the wall. A proper james hardie fire rated wall system nz always specifies the type and density of insulation required.

The most commonly specified materials are high-density mineral wool or glass wool insulation batts. These materials are non-combustible and are designed to fit snugly between the wall studs, eliminating gaps where heat could penetrate. The thickness and density of the insulation are precisely calculated for each specific FRR.

Using incorrect or poorly fitted insulation is a major compliance risk. It can drastically reduce the system’s ability to prevent dangerous temperature rises on the non-fire side of the wall. Therefore, only the insulation specified in the James Hardie technical literature for the chosen james hardie fire rated wall system nz should be used.

Linings and Claddings: The Protective Layers

The linings and external claddings are the first line of defence in the wall assembly. James Hardie offers a range of fire-resistant fibre cement sheets for this purpose, such as Villaboard™ Lining for internal use and RAB™ Board for external applications. The number of layers and the thickness of these sheets are key variables in the system’s design.

For higher FRRs, multiple layers of fibre cement board may be required on one or both sides of the frame. The specific arrangement is detailed in the system specifications to achieve ratings from 30 minutes up to 120 minutes or more. The performance of a james hardie fire rated wall system nz relies heavily on the correct application of these layers.

Fasteners and jointing systems are equally important in maintaining the integrity of the protective layers. Specialised fire-rated screws, sealants, and compounds must be used as specified. These elements ensure that joints, corners, and penetrations do not become weak points during a fire event.

Key Applications for James Hardie Fire Systems

James Hardie fire-rated systems are versatile and can be used in a wide range of construction projects across New Zealand. Their primary function is to create fire-safe compartments within a building, slowing the spread of fire. This is particularly important in multi-unit residential and commercial buildings.

The application of a james hardie fire rated wall system nz is determined by the building’s use, height, and proximity to other properties. Common applications include intertenancy walls, boundary walls, corridor walls, and shaft walls. Each application has specific FRR requirements under the NZBC.

Choosing the correct system for a specific application requires a thorough understanding of the building code and the performance characteristics of the available systems. James Hardie provides extensive technical support to help architects, designers, and builders select the most appropriate solution. The integrity of a james hardie fire rated wall system nz is vital for occupant safety.

Intertenancy Wall Systems

In multi-unit dwellings such as apartments, townhouses, and terraced homes, intertenancy walls are a critical safety feature. These walls separate individual occupancies or tenancies from one another. Their primary purpose is to prevent the spread of fire and sound between units.

The New Zealand Building Code mandates strict fire and acoustic ratings for intertenancy walls. A james hardie fire rated wall system nz provides an effective solution, often achieving FRRs of 60/60/60 or higher, along with excellent acoustic separation. This dual performance is a significant advantage in modern high-density housing projects.

Systems like the Hardie™ Gypsum Fire and Acoustic Wall System are specifically designed for this purpose. They combine the robustness of fibre cement with gypsum board to deliver a high-performance, cost-effective solution. The correct installation of the james hardie fire rated wall system nz in these applications is paramount for the safety and comfort of residents.

Boundary and External Wall Systems

Walls built close to a property boundary line pose a unique fire risk. They must be designed to prevent fire from spreading from a neighbouring property to the building, or vice versa. The NZBC defines specific requirements for the fire rating of external walls based on their distance from the boundary.

A james hardie fire rated wall system nz is frequently specified for these zero-lot-line or close-to-boundary situations. Products like RAB™ Board are often used as part of the external wall assembly. This provides not only the required FRR but also acts as a rigid air barrier for weather-tightness and structural bracing.

These external fire-rated systems must be designed to withstand both internal fire scenarios and external fire exposure. The system’s design ensures it maintains its integrity and insulation performance regardless of the fire’s origin. Specifying a compliant james hardie fire rated wall system nz is a critical step in managing risk for properties built in close proximity.

Fire-Rated Corridors and Shafts

Corridors are essential exit routes in commercial and multi-residential buildings. They must be protected to ensure occupants can evacuate safely during a fire. The walls lining these corridors must therefore have a specific FRR to prevent fire from breaking into the escape path.

A james hardie fire rated wall system nz provides a reliable solution for constructing fire-rated corridor walls. These systems ensure that egress routes remain structurally sound and protected from flames and excessive heat for a specified duration. The choice of system depends on the building’s height and occupancy type.

Similarly, service shafts for elevators, plumbing, and electrical systems can act as chimneys in a fire, allowing it to spread rapidly between floors. Encasing these shafts with a high-performance james hardie fire rated wall system nz is a critical fire-stopping measure. This containment strategy is a fundamental principle of fire-safe building design.

Penetrations and Junctions

Any fire-rated wall is only as strong as its weakest point. Penetrations for services like pipes, ducts, and electrical cables must be correctly sealed to maintain the wall’s FRR. Unprotected openings can completely negate the performance of an otherwise compliant wall.

A compliant james hardie fire rated wall system nz includes detailed specifications for treating these penetrations. This involves using tested and approved fire-stopping products, such as fire-rated collars, sealants, and mortars. These products are designed to expand when heated, sealing the gap and preventing the passage of fire and smoke.

The junctions between fire-rated walls and other building elements, like floors and ceilings, also require careful attention. These intersections must be designed and constructed to maintain continuity of the fire separation. The James Hardie technical literature provides tested details for these critical junctions, ensuring the entire compartment is secure. The installation of a james hardie fire rated wall system nz must account for these details meticulously.

Installation and Compliance for a James Hardie Fire Rated Wall System NZ

A fire-rated system a a is only effective if it is built exactly as it was tested. Strict adherence to the manufacturer’s installation instructions is not just recommended; it is a requirement for compliance. Any deviation can render the system non-compliant and compromise building safety.

The primary resource for installers is the James Hardie Fire and Acoustic Design Manual. This document provides comprehensive details for every tested james hardie fire rated wall system nz. It includes information on framing, linings, insulation, fasteners, jointing, and penetration sealing.

In New Zealand, it is crucial that the installation is carried out by competent and preferably licensed building practitioners (LBPs). These professionals have the knowledge and skills to understand the technical specifications and execute the installation correctly. Proper installation is the final, critical step in delivering the life-saving performance of a james hardie fire rated wall system nz.

The Importance of Technical Literature

The James Hardie technical manuals are the definitive source of truth for system design and installation. These documents are the result of extensive research, development, and independent fire testing conducted at accredited laboratories. The details within are not guidelines; they are mandatory instructions.

Before beginning any project, architects, builders, and installers must ensure they have the latest version of the relevant manual. James Hardie regularly updates its literature to reflect new test data, product improvements, and changes in the building code. Relying on outdated information is a significant risk for any james hardie fire rated wall system nz.

The manuals provide clear, illustrated details for a wide range of scenarios, from standard wall construction to complex junctions and service penetrations. Following these details precisely ensures that the as-built wall performs as intended in a fire. This documentation is also vital for the building consent process and for demonstrating compliance to council inspectors. This is why a proper james hardie fire rated wall system nz relies on its literature.

On-Site Quality Assurance and Inspection

Effective quality assurance throughout the construction process is essential for fire-rated systems. This involves regular checks to ensure that the correct materials are being used and that installation practices align with the specifications. A small error, like using the wrong screw type or spacing, can have a major impact on fire performance.

Site supervisors and project managers play a key role in overseeing the installation of a james hardie fire rated wall system nz. They should conduct regular inspections, particularly before the linings are fixed in place, to verify framing and insulation details. Photographic evidence of each stage of construction is also a valuable practice for compliance records.

Building Consent Authorities (BCAs) will also conduct their own inspections at key stages of the project. They will require evidence that the fire-rated systems have been installed in accordance with the consented plans and the manufacturer’s literature. Failing an inspection can lead to costly delays and rework, highlighting the importance of getting the james hardie fire rated wall system nz installation right the first time.

Producer Statements and Documentation

In New Zealand’s building control system, Producer Statements (PS) are an important part of the compliance pathway. A PS-3 (Producer Statement – Construction) is often provided by the installer to certify that the fire-rated systems have been installed according to the specified design. This is a formal declaration of compliance.

To issue a PS-3, the installer must have confidence that every aspect of the james hardie fire rated wall system nz has been completed correctly. This requires meticulous record-keeping, including material delivery dockets, batch numbers, and photographic documentation of the installation process. This traceability is crucial for accountability.

This documentation provides the BCA and the building owner with assurance that the passive fire protection systems are fit for purpose. It forms a critical part of the final Code Compliance Certificate (CCC) documentation. A well-documented james hardie fire rated wall system nz project simplifies the compliance process and provides long-term peace of mind.

Common Installation Errors to Avoid

Even with detailed instructions, installation errors can occur. One of the most common issues is the incorrect substitution of materials. Using a different brand of insulation or a non-specified sealant can invalidate the entire system’s fire rating. Every component of a james hardie fire rated wall system nz has been chosen and tested for a reason.

Another frequent error relates to fasteners. Using the wrong type, length, or spacing of screws can lead to a premature failure of the linings in a fire. Similarly, improper jointing or poorly sealed penetrations create clear pathways for fire and smoke to travel through the wall.

Gaps in insulation or insulation that is compressed or poorly fitted can also severely compromise the system’s performance. Installers must be trained to pay close attention to these details. A robust understanding of how a james hardie fire rated wall system nz works is the best defence against these common and dangerous mistakes. Diligence in every step is required.

The Advantages of Specifying James Hardie

Choosing a james hardie fire rated wall system nz offers numerous benefits beyond just meeting the minimum requirements of the building code. The company has a long-standing reputation for quality, innovation, and rigorous testing. This provides architects and builders with a high degree of confidence in the performance of their products.

One of the key advantages is the comprehensive nature of the systems and the supporting technical documentation. James Hardie provides a complete solution, with all components tested together to ensure compatibility and predictable performance. This integrated approach simplifies the specification and construction process.

Furthermore, James Hardie products offer additional benefits such as durability, resistance to moisture and rot, and excellent acoustic performance. This means a single wall system can solve multiple design challenges simultaneously. Specifying a james hardie fire rated wall system nz is an investment in the long-term safety, durability, and comfort of the building.

Conclusion: A Commitment to Fire Safety

In the field of building construction, fire safety is a responsibility of the highest order. The use of reliable, tested, and compliant passive fire protection systems is fundamental to protecting lives and assets. The choice of a wall system can have profound consequences in the event of a fire.

A james hardie fire rated wall system nz represents a commitment to achieving a superior level of safety and compliance. These systems are the result of extensive research, development, and independent testing designed to meet the specific demands of the New Zealand Building Code. They provide a robust and dependable solution for creating fire-safe compartments in all types of buildings.

By understanding the components, following the detailed installation literature, and ensuring quality at every step, designers and builders can leverage the full potential of a james hardie fire rated wall system nz. This ensures not only compliance with regulations but also delivers genuine peace of mind. Ultimately, it provides occupants with the most valuable thing of all: time.