Why Fire-Rated Wall Systems Are Non-Negotiable in New Zealand

Complete Guide to James Hardie Fire Wall Systems in New Zealand – The New Zealand Building Code (NZBC) sets out stringent requirements for fire safety in all construction projects. These regulations are not merely suggestions; they are legally enforceable standards designed to save lives. They ensure that in the event of a fire, occupants have sufficient time to escape, and the fire’s spread is contained, protecting adjacent properties.

Failure to comply with these codes carries severe consequences, including legal liability, costly rectification work, and irreparable damage to your professional reputation. More importantly, it puts lives at risk. Therefore, specifying and installing a fully compliant, high-performance fire-rated wall system is a fundamental responsibility for every professional in the industry.

Beyond mere compliance, a robust fire wall system is a mark of quality and a commitment to excellence. It demonstrates a duty of care to the end-user, whether they are a family in their home or employees in a commercial space. Investing in superior fire protection is investing in certainty, security, and the long-term integrity of your buil, Complete Guide to James Hardie Fire Wall Systems in New Zealand.

Introducing James Hardie: The Gold Standard in Fire Protection

For over a century, James Hardie has been a global leader in fibre cement technology, pioneering building materials that are as durable as they are beautiful. This legacy is built on a foundation of relentless innovation and an unwavering commitment to safety. James Hardie doesn’t just sell products; they deliver comprehensively tested, fully integrated systems designed to perform under the most extreme conditions.

When it comes to fire protection, the James Hardie name is synonymous with trust and reliability. Their fire wall systems are engineered to meet and exceed the rigorous demands of the New Zealand Building Code. By choosing James Hardie, you are specifying a solution that has been meticulously designed, exhaustively tested, and proven to deliver life-saving performance.

This commitment extends to every component of the system, creating an unbroken chain of protection. From the fibre cement sheets to the specialised fasteners and cavity solutions, every element works in harmony. This system-based approach eliminates guesswork and provides absolute confidence in the final Fire Resistance Rating (FRR) of your assembly.

The Science Behind Fibre Cement’s Fire Resistance

The remarkable fire-resistant properties of James Hardie products are rooted in their core composition. Fibre cement is a composite material made from a simple but powerful blend of cement, sand, water, and a small amount of cellulose fibre. This unique formulation results in a product that is inherently non-combustible.

Unlike timber or vinyl-based claddings, James Hardie fibre cement will not ignite when exposed to a direct flame, nor will it contribute fuel to a fire. It does not burn, melt, or produce toxic smoke, which are critical factors in maintaining structural integrity and ensuring safe egress during an emergency. This inherent stability buys precious time when it matters most.

This non-combustibility is a passive, built-in feature that remains effective for the life of the building. It doesn’t degrade, require re-treatment, or rely on chemical additives for its performance. It is simply, and powerfully, resistant to fire by its very nature.

Beyond Fire: The Added Benefits of James Hardie Systems

While fire resistance is a paramount feature, the value proposition of James Hardie systems extends far beyond this single attribute. Specifying these systems brings a multitude of benefits that enhance the overall quality, longevity, and value of any project. This holistic performance is what makes James Hardie the intelligent choice for discerning professionals.

James Hardie products are engineered to withstand New Zealand’s harshest weather conditions, from driving rain and high winds to intense UV exposure. They are resistant to rotting, warping, and moisture damage, ensuring the building envelope remains weathertight and durable for decades. This resilience translates into fewer call-backs and a superior finished product.

Furthermore, the dimensional stability and extensive range of finishes offer incredible design flexibility without compromising on a single performance metric. With minimal maintenance requirements and a long service life, James Hardie systems deliver a low total cost of ownership. This makes them a sound investment for both the builder and the property owner.

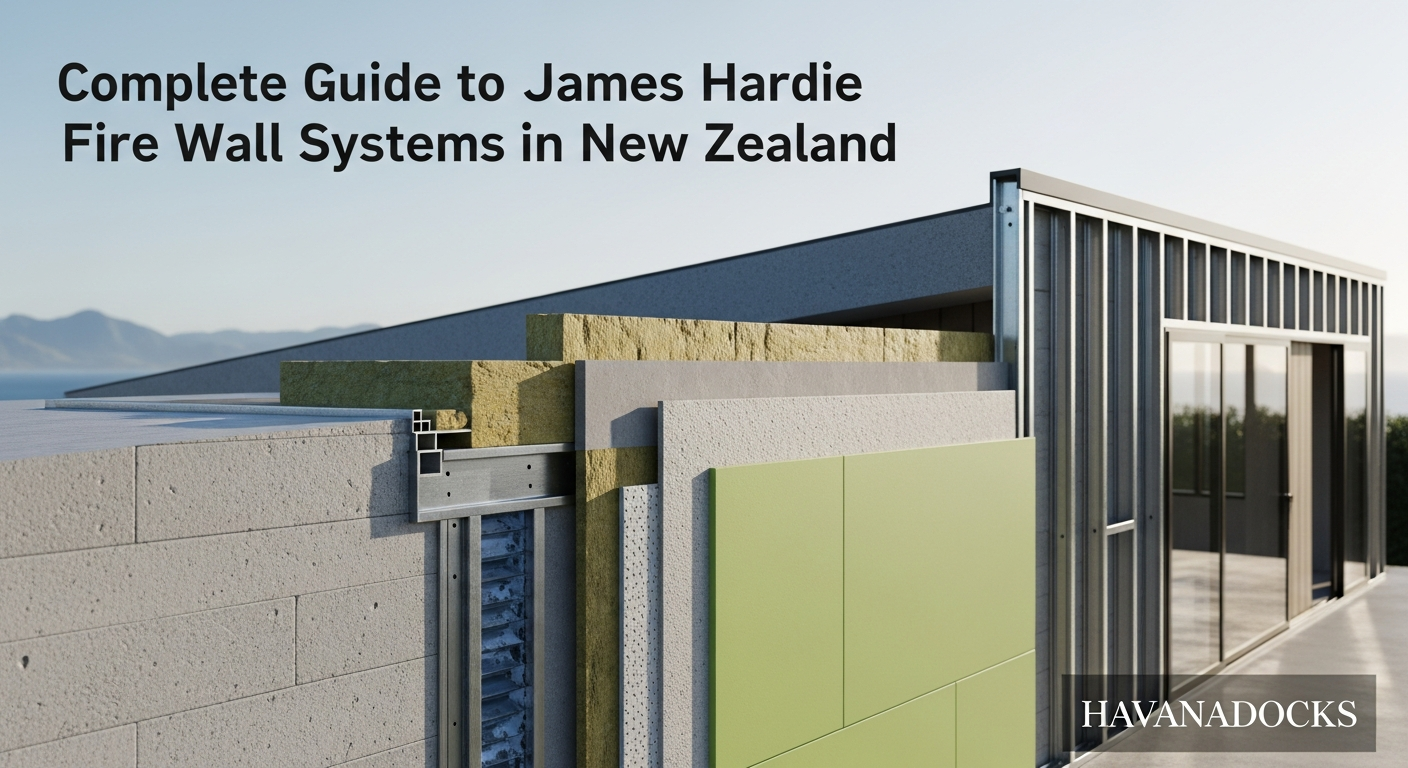

A System Approach to Uncompromised Safety

A critical mistake in building design is viewing components in isolation. A fire wall is only as strong as its weakest link. This is why James Hardie champions a complete system approach, where every component is designed to work together seamlessly to achieve the specified Fire Resistance Rating.

This means that the fibre cement sheets, the framing, the fasteners, the sealants, and the cavity construction are all part of a single, codemarked, and warrantied solution. Using non-specified or third-party components can compromise the integrity of the entire wall assembly, potentially voiding the warranty and, most critically, failing to deliver the life-saving performance required. The system is tested as a whole to guarantee performance.

By specifying a complete James Hardie system, including crucial elements like the james hardie horizontal cavity batten nz, you are removing uncertainty. You are building with a solution that has been rigorously tested in accredited laboratories to verify its FRR for stability, integrity, and insulation. This provides irrefutable proof of compliance and performance for consenting authorities and clients alike.

The Critical Role of the Cavity System in Performance

In modern New Zealand construction, the cavity system behind the cladding is one of the most vital elements of the building envelope. It serves multiple crucial functions that contribute to the health, durability, and safety of the structure. A correctly designed and installed cavity is fundamental to performance.

The primary role of a cavity is to manage moisture. It creates an air gap that allows any incidental moisture that gets behind the cladding to drain away freely and promotes airflow to dry the structure. This is essential for preventing moisture build-up, which can lead to rot, mould, and long-term structural degradation.

However, in a fire-rated system, the cavity’s role is even more significant. It forms an integral part of the tested wall assembly, influencing how heat is transferred and how the structure behaves under fire conditions. The components used to create this cavity must therefore be non-combustible and designed to maintain their integrity when exposed to extreme heat.

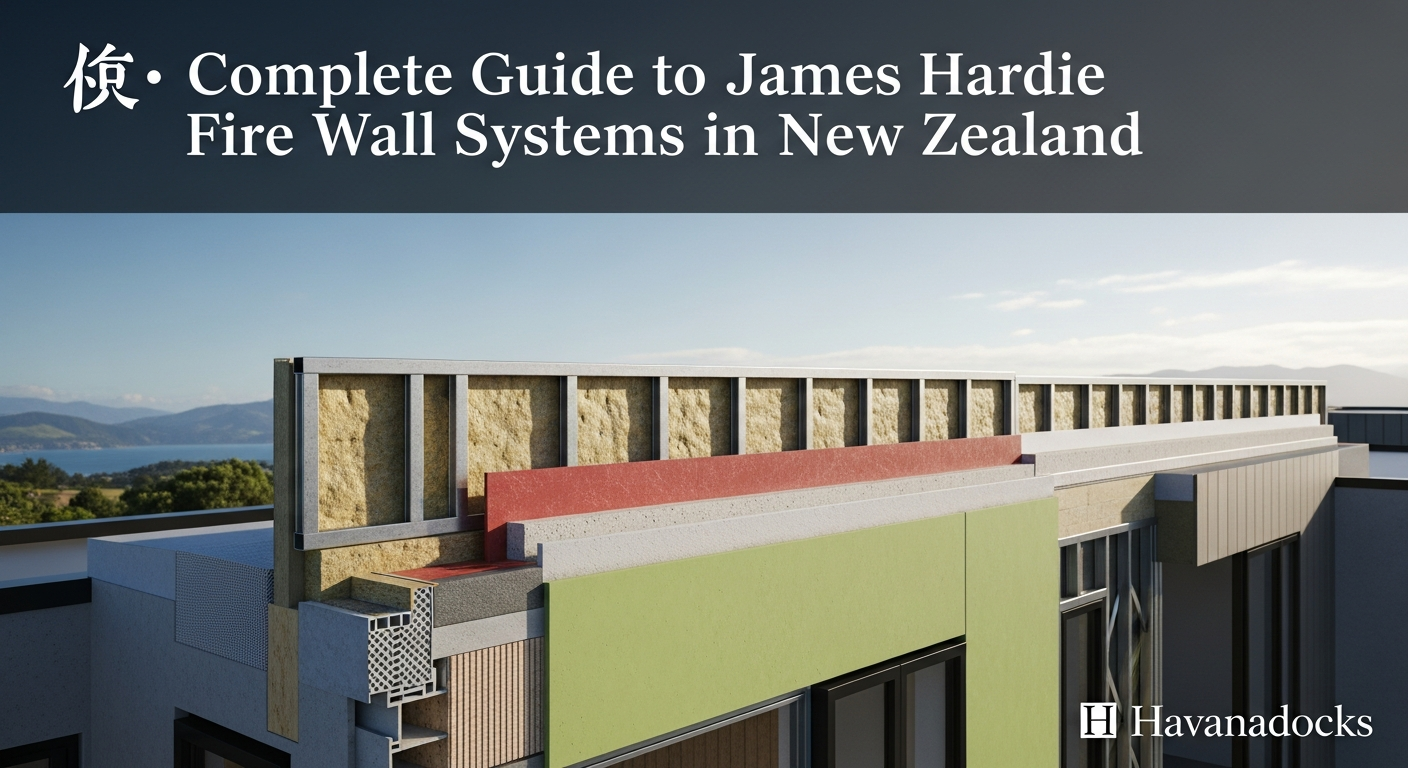

Understanding the Drained and Vented Cavity

A drained and vented cavity system is considered best practice in New Zealand, especially for buildings in higher-risk wind zones. This system creates a clear, unobstructed path for water to drain down and exit at the base of the wall. It also allows for convectional airflow, which helps to equalise pressure and actively dry the cavity space.

This continuous ventilation is key to the long-term health of the building, ensuring the framing and insulation remain dry and effective. For a fire-rated assembly, maintaining the precise depth and structure of this cavity is paramount. Any deviation can alter the wall’s thermal performance and compromise its certified Fire Resistance Rating.

Traditionally, creating this cavity has involved timber battens, which introduce a combustible element into a non-combustible system. This can create a point of failure in a fire scenario. Furthermore, achieving perfectly straight and true installation with timber can be time-consuming and challenging, potentially leading to inconsistencies in the cavity depth.

The Innovation of the James Hardie Horizontal Cavity Batten NZ

To address the challenges of traditional cavity construction, James Hardie developed a groundbreaking solution specifically for the New Zealand market. The james hardie horizontal cavity batten nz is a purpose-designed, non-combustible component that revolutionises the creation of cavity spaces. It is the missing link that perfects the fire-rated wall system.

Engineered from steel, the james hardie horizontal cavity batten nz provides exceptional strength and dimensional stability. Unlike timber, it will not burn, rot, warp, or twist, ensuring the integrity of the cavity is maintained for the life of the building and, crucially, during a fire. This makes it an essential component for achieving a robust and truly non-combustible wall assembly.

This innovative product is more than just a piece of metal; it is a key enabler of faster, more accurate, and more reliable construction. The introduction of the james hardie horizontal cavity batten nz has simplified installation while significantly enhancing the overall performance and safety of the final wall system. Opting for the james hardie horizontal cavity batten nz is a clear choice for superior performance. The reliability of the james hardie horizontal cavity batten nz is unmatched in the industry.

Many leading architects now exclusively specify the james hardie horizontal cavity batten nz for their projects. Using the james hardie horizontal cavity batten nz streamlines the pathway to compliance. The technical documentation supporting the james hardie horizontal cavity batten nz is comprehensive and readily available. For any fire-rated wall, the james hardie horizontal cavity batten nz is the superior choice.

The system’s performance hinges on the inclusion of the james hardie horizontal cavity batten nz. When considering alternatives, the benefits of the james hardie horizontal cavity batten nz become immediately apparent. The durability of the james hardie horizontal cavity batten nz ensures a long-lasting, high-performance building envelope. Installing a cladding system is made easier with the james hardie horizontal cavity batten nz.

Streamlining Installation with the James Hardie Horizontal Cavity Batten NZ

For builders and installers on site, time is money. The james hardie horizontal cavity batten nz is designed with installation efficiency at its core, helping to reduce labour costs and accelerate project timelines. Its pre-formed, consistent profile eliminates the need for sorting and straightening timber, ensuring a perfect cavity depth every time.

The battens are lightweight and easy to handle, and their design includes features that simplify fixing to the framing. This precision means that cladding installation is faster and results in a flatter, more uniform finish. The james hardie horizontal cavity batten nz helps to de-skill a critical part of the building process, delivering consistent, high-quality results regardless of the installer’s experience level. The efficiency gained by using the james hardie horizontal cavity batten nz is a significant project advantage. This is a key reason why the james hardie horizontal cavity batten nz is so popular.

This streamlined process not only saves time but also reduces the potential for error. An incorrectly formed cavity can lead to significant weathertightness or compliance issues down the track. By using the purpose-made james hardie horizontal cavity batten nz, you are building quality and compliance in from the start, minimising the risk of costly rework. The precision engineering of the james hardie horizontal cavity batten nz guarantees a flawless substrate for cladding.

The entire team benefits when the james hardie horizontal cavity batten nz is specified for the job. Site supervisors appreciate the simplicity and reliability offered by the james hardie horizontal cavity batten nz. Contractors report significant time savings when they switch to the james hardie horizontal cavity batten nz. The straightforward nature of the james hardie horizontal cavity batten nz helps keep projects on schedule.

Ensuring Compliance and Performance with the James Hardie Horizontal Cavity Batten NZ

From a specifier’s or architect’s perspective, the primary goal is to design a building that is safe, compliant, and performs as intended. The james hardie horizontal cavity batten nz provides absolute certainty in this regard. As a non-combustible component within a fully tested James Hardie fire system, its inclusion is key to achieving the specified Fire Resistance Rating.

Using a combustible timber batten in a fire-rated wall adds a variable that can compromise the system’s performance. The james hardie horizontal cavity batten nz eliminates this risk entirely. Its steel construction ensures it will not contribute to the spread of flame, maintaining the structural integrity of the cavity and the overall wall assembly when it is needed most. Specification documents are simplified with the inclusion of the james hardie horizontal cavity batten nz.

Furthermore, because the james hardie horizontal cavity batten nz is an integral part of the codemarked James Hardie system, it simplifies the consenting process. Council officials and building inspectors recognize the james hardie horizontal cavity batten nz as part of a trusted, compliant solution. This clear pathway to compliance avoids ambiguity and potential delays, ensuring your project progresses smoothly from design to completion. Ensuring system performance is the core function of the james hardie horizontal cavity batten nz.

When the stakes are high, specifying the james hardie horizontal cavity batten nz is the prudent choice. The peace of mind that comes from using the james hardie horizontal cavity batten nz is invaluable. For a fully integrated and tested solution, the james hardie horizontal cavity batten nz is essential. The technical support behind the james hardie horizontal cavity batten nz gives specifiers complete confidence. Every detail matters, which is why the james hardie horizontal cavity batten nz was developed.

Specifying the Right James Hardie Fire Wall System for Your Project

James Hardie offers a comprehensive suite of fire-rated wall systems, each designed to meet specific performance requirements and building applications. Choosing the right system depends on factors such as the building type, its proximity to boundaries, and the required Fire Resistance Rating (FRR). These ratings are expressed in minutes for three key criteria: Stability / Integrity / Insulation (e.g., 60/60/60).

For intertenancy walls in multi-unit residential projects, systems incorporating products like HardieFlex™ Lining and Villaboard™ Lining offer excellent fire and acoustic separation. These systems are designed to provide robust protection between dwellings, preventing the spread of fire and reducing noise transmission. They deliver a high level of safety and amenity for occupants.

For external walls requiring a fire rating, James Hardie offers solutions using products like RAB™ Board as a rigid air barrier, combined with a range of aesthetic exterior cladding options. These systems provide a continuous, non-combustible barrier that protects the building structure from fire exposure. Crucially, these systems are designed to be installed over cavity solutions that can incorporate the james hardie horizontal cavity batten nz to ensure complete performance. The choice of the james hardie horizontal cavity batten nz will elevate the performance of any specified system.

Conclusion: Build with Confidence, Choose James Hardie for Unrivalled Protection

In construction, there are no second chances when it comes to fire safety. The decisions made at the design and specification stage have a lasting impact on the safety of those who will live and work within the structures you create. It is a responsibility that demands the very best materials and systems available.

James Hardie provides more than just building products; they deliver complete, rigorously tested fire wall systems that offer unparalleled protection and peace of mind. From the inherent non-combustibility of their advanced fibre cement to the intelligent design of components like the james hardie horizontal cavity batten nz, every element is engineered for uncompromised performance. Choosing James Hardie is choosing a legacy of trust, a commitment to innovation, and a guarantee of compliance.

Build with confidence, build with certainty, and protect your legacy by specifying James Hardie fire wall systems for your next project. By embracing this system-based approach, you ensure the integrity of your design, the safety of the occupants, and the enduring quality of your work. Contact your James Hardie representative today to discover the right fire-rated solution for your specific needs.