The Best Cavity Batten System NZ Builders Trust: A Comprehensive Guide

Best Cavity Batten Systems in New Zealand: A Builder’s Guide – In New Zealand’s demanding climate, the difference between a building that lasts a lifetime and one plagued by costly failures often lies hidden behind the cladding. For decades, the construction industry has grappled with the critical challenge of moisture management. The lessons learned from the leaky building crisis have fundamentally reshaped our approach, placing a non-negotiable emphasis on robust, well-designed building envelopes.

At the heart of this modern, resilient approach is the cavity system, and its most vital component: the batten. Choosing the right batten is no longer a minor detail; it is a pivotal decision that impacts a building’s durability, the efficiency of your build, and your reputation as a quality builder. This guide is designed to navigate the options and highlight why selecting the best cavity batten system NZ offers is a cornerstone of superior construction.

Why Cavity Systems Are Non-Negotiable in NZ Construction

New Zealand’s weather is as beautiful as it is unforgiving, with high rainfall and humidity being a constant reality for much of the country. This environmental pressure puts building envelopes to the ultimate test, where even the smallest imperfection can lead to moisture ingress. The systematic failures of the past taught us that a single line of defence is simply not enough.

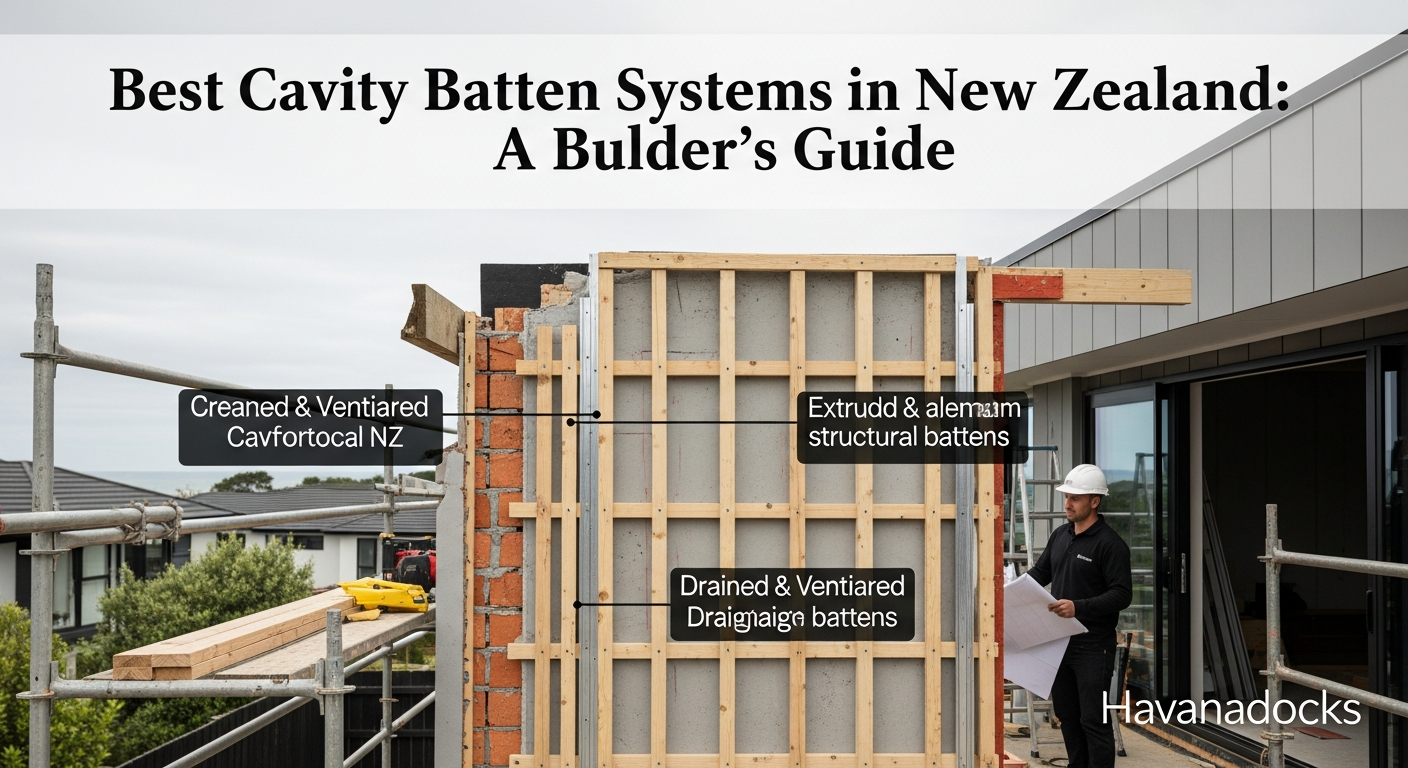

A cavity system creates an essential air gap between the cladding and the building wrap on the structural framing. This space is a critical buffer zone designed to manage any water that bypasses the outer cladding layer. Its function is elegantly simple yet fundamentally important for the health of the building.

The principles of weathertightness, often referred to as the “4 Ds,” are directly enabled by a well-executed cavity. These principles are Deflection (the cladding), Drainage (the cavity), Drying (airflow within the cavity), and Durability (of the materials used). The cavity batten is the very component that creates this drainage and drying path, making it the unsung hero of a weathertight home.

Without a properly functioning cavity, trapped moisture can lead to a cascade of devastating problems. These issues include timber rot, toxic mould growth, and the catastrophic failure of structural components. Consequently, a correctly installed cavity system isn’t just a building code requirement; it’s your primary insurance policy against moisture-related defects and costly call-backs.

The Evolution of Cavity Battens: From Timber to Advanced Polymers

The humble cavity batten has undergone a significant transformation over the years, evolving in response to a deeper understanding of building science and the need for greater performance. This evolution reflects a journey from traditional, familiar materials to sophisticated, engineered solutions. Understanding this progression is key to appreciating why modern systems deliver superior results and why the search for the best cavity batten system NZ has intensified.

The Traditional Choice: Timber Battens

For many years, treated timber was the default choice for cavity battens. It was readily available, inexpensive, and a material every builder was familiar with working with. Builders could rip down timber on-site to create the battens needed for the job.

However, experience has revealed the inherent drawbacks of timber in this critical application. The quality of treatment (such as H3.1) can be inconsistent, and any cuts or notches made on-site compromise this protective barrier, creating a new vulnerability. Furthermore, timber is dimensionally unstable, prone to warping, twisting, and swelling when it absorbs moisture, which can compromise the cavity’s integrity and put stress on cladding fixings.

Even when treated, wood remains an organic material susceptible to moisture-related degradation over its lifespan. This has led specifiers and builders to seek out more reliable and durable alternatives. The quest for a more stable and resilient solution was a direct response to the shortcomings of the traditional approach.

The Rise of Plastic and uPVC Battens

The first wave of innovation brought simple plastic, polypropylene, and uPVC battens to the market. These materials offered immediate and obvious advantages over timber. They are completely impervious to moisture, meaning they will not rot, swell, or support mould growth.

This shift represented a significant step forward in durability and dimensional stability. Plastic battens provide a consistent cavity depth, free from the knots, twists, and imperfections of timber. This consistency makes for a flatter, more uniform substrate for cladding installation.

While a major improvement, these early plastic battens were often simple, solid profiles. They solved the rot problem but didn’t necessarily enhance the cavity’s other primary function: drying. The market was ready for the next step, a system that didn’t just resist water but actively promoted ventilation.

The Modern Solution: Vented and Profiled Batten Systems

The pinnacle of batten evolution is the modern, engineered polymer system. These are not just strips of plastic; they are intelligently designed components that enhance the performance of the entire wall assembly. Finding the best cavity batten system NZ now means looking for these advanced features.

These next-generation battens feature sophisticated profiles with built-in ventilation channels, ridges, and fins. This design dramatically increases airflow within the cavity, accelerating the drying process. By creating a clear, unobstructed path for air to move from the bottom of the wall to the top, these systems ensure that any residual moisture evaporates quickly and efficiently.

This active “breathing” function is a game-changer for building envelope health. It ensures the framing timber stays drier, preserving its structural integrity and preventing the conditions that lead to rot and mould. These advanced systems represent a proactive approach to moisture management, moving beyond passive drainage to active, convective drying.

Key Factors in Choosing the Best Cavity Batten System NZ Offers

When you’re on the tools, every product choice has a ripple effect on your workflow, your project’s timeline, and the final quality of your work. Selecting a cavity batten is no different. The best cavity batten system NZ builders can use is one that excels across several key performance criteria, from the raw material itself to the ease of installation.

Material Performance and Durability

The long-term resilience of a building starts with the durability of its components. The batten, though concealed, is under constant pressure from cladding weight and environmental exposure. Therefore, its material composition is of paramount importance.

An ideal batten system should be manufactured from a high-quality, impact-resistant, and UV-stabilised polymer. This ensures it won’t become brittle over time from sunlight exposure during construction or from long-term temperature fluctuations within the cavity. The material must be completely inert, guaranteeing it won’t react with timber treatments, building wrap coatings, or cladding materials.

Furthermore, look for products that have been rigorously tested and appraised by trusted third-party organisations like BRANZ. A BRANZ appraisal provides independent verification that the system meets or exceeds the New Zealand Building Code requirements. This is your assurance that the product is fit for purpose and will perform as promised for the life of the building, which is crucial when searching for the best cavity batten system NZ market provides.

Installation Efficiency and Labour Savings

Time is the most valuable currency on any construction site. A product that is difficult, slow, or finicky to install directly erodes your profitability. The best cavity batten system NZ builders can adopt should be one that actively saves time and reduces labour costs.

Modern polymer systems are incredibly lightweight compared to timber, making them easier to handle, transport around the site, and cut. This reduces fatigue and speeds up the entire installation process. Many systems are designed to be easily scored and snapped, eliminating the need for power saws for simple cuts and further accelerating workflow.

Beyond just the material itself, the design of the system plays a huge role in efficiency. Features that simplify alignment, spacing, and fixing can shave hours, or even days, off a project’s timeline. This is where engineered systems truly outshine basic, generic alternatives.

Interlocking Systems and Self-Spacing Features

One of the most significant innovations in batten design is the development of interlocking and self-spacing features. These systems often incorporate a tongue-and-groove or click-lock mechanism. This seemingly simple feature offers profound benefits on-site.

It completely eliminates the guesswork and tedious measurement required to maintain a perfectly consistent cavity depth and batten alignment. The interlocking design ensures that each batten installs straight and true, creating a flawless plane for the cladding. This is particularly valuable over long, uninterrupted walls where maintaining a straight line with individual timber battens can be challenging and time-consuming. This feature alone is a strong qualifier for the best cavity batten system NZ has to offer.

Compatibility with Cladding and Building Wraps

A cavity batten does not work in isolation; it’s part of an integrated wall assembly. Its design must be compatible with the other critical components, namely the building wrap and the chosen cladding system. The wrong batten can compromise the performance of these other layers.

Some basic plastic battens have sharp edges that can scuff, tear, or wear away at the building wrap during installation or over time due to building movement. The best cavity batten system NZ will feature a design with rounded or “soft” edges where it meets the wrap. This protects the wrap’s integrity, which is your primary air and water barrier.

Additionally, the system must provide a robust and stable fixing surface for a wide range of cladding types, from lightweight fibre cement sheets to heavy timber weatherboards. Look for systems that specify approved fixing patterns and have been tested for compatibility with popular New Zealand cladding products. This ensures the entire system works in harmony to deliver ultimate weathertightness and structural stability.

Spotlight on a Leading Solution: Next-Generation Vented Polymer Systems

In a competitive market, a few systems rise above the rest by holistically addressing every challenge a builder faces. The ultimate solution—the true best cavity batten system NZ builders should be looking for—is a next-generation vented polymer system. This isn’t just a product; it’s an engineered approach to moisture management that delivers unmatched performance, durability, and on-site efficiency.

Imagine a system crafted from a toughened, co-polymer blend, engineered for extreme durability and a 50+ year lifespan. It’s lightweight yet incredibly strong, capable of supporting heavy cladding loads without flexing or fatiguing. This advanced material is completely impervious to moisture, ensuring it will never rot, warp, or provide a food source for mould or insects.

The true genius of these systems lies in their intricate design. Instead of a simple flat profile, they feature a matrix of deep, vertical ventilation channels—often three or more per batten. This advanced, multi-fin profile creates unparalleled levels of N-S (North-South) cross-sectional airflow within the cavity, actively pulling moisture-laden air up and out of the wall assembly.

This level of ventilation dramatically accelerates drying, turning the cavity from a passive drainage plane into an active “breathing” lung for the building. It ensures the structural framing stays significantly drier, even in the wettest conditions. This proactive drying capability is what sets the best cavity batten system NZ apart from all others.

The benefits extend directly to the installation process, where smart design translates into significant time and money savings. These premium systems incorporate robust, positive-feel interlocking mechanisms. This feature not only guarantees perfect 20mm spacing but also makes installation faster and more intuitive, reducing the chance of human error.

Many are designed with unique profiles that create minimal contact with the building wrap. The pressure points are spread across smooth, flat surfaces, completely eliminating the risk of point-loading or abrasion that can compromise the wrap. This thoughtful design shows a deep understanding of how the entire wall system must work together.

Furthermore, these systems offer a complete solution, not just individual battens. They often include purpose-built components like ventilated vermin-proof starter strips and cavity closers. This ensures the integrity of the system is maintained around the entire building envelope, providing a seamless and fully integrated approach to weathertightness.

When you specify such a system, you are doing more than just meeting the code. You are investing in a higher standard of construction that protects your work, enhances your reputation, and delivers a healthier, more durable building for your client. The efficiency gains on-site are a direct financial benefit, while the long-term performance provides peace of mind that is truly priceless. The search for the best cavity batten system NZ culminates in a solution that is smarter, faster, and demonstrably better for the building.

Conclusion: Making the Smart Choice for a Weathertight Future

The choice of a cavity batten is a foundational decision in modern New Zealand construction. We have moved far beyond the days of simply using treated timber off-cuts. Today, the market offers sophisticated, engineered solutions designed to provide a new level of performance and protection against our unique climate.

From the inherent flaws of timber to the revolutionary efficiency of interlocking, vented polymer systems, the evolution has been driven by a relentless pursuit of durability and building excellence. The key factors—material durability, installation speed, and system compatibility—all point towards these advanced solutions as the superior choice. Investing in the best cavity batten system NZ has to offer is not an expense; it is a critical investment in risk mitigation, construction efficiency, and your professional reputation.

Ultimately, protecting your legacy as a builder means constructing homes that are not just beautiful, but also healthy, dry, and resilient for generations to come. By choosing an advanced, vented cavity batten system, you are building smarter, not harder. You are ensuring the long-term integrity of your work and providing your clients with the peace of mind they deserve.