The Crucial Role of Wall Ventilation in Modern Construction

James Hardie Wall Ventilation System: Complete Guide – Proper wall ventilation is fundamental to the long-term health and durability of any building. As homes and commercial structures become more airtight to improve energy efficiency, the risk of trapping moisture within the wall cavity increases significantly. This trapped moisture, from sources like rain penetration, condensation, or indoor humidity, can lead to serious problems such as mold, mildew, and rot.

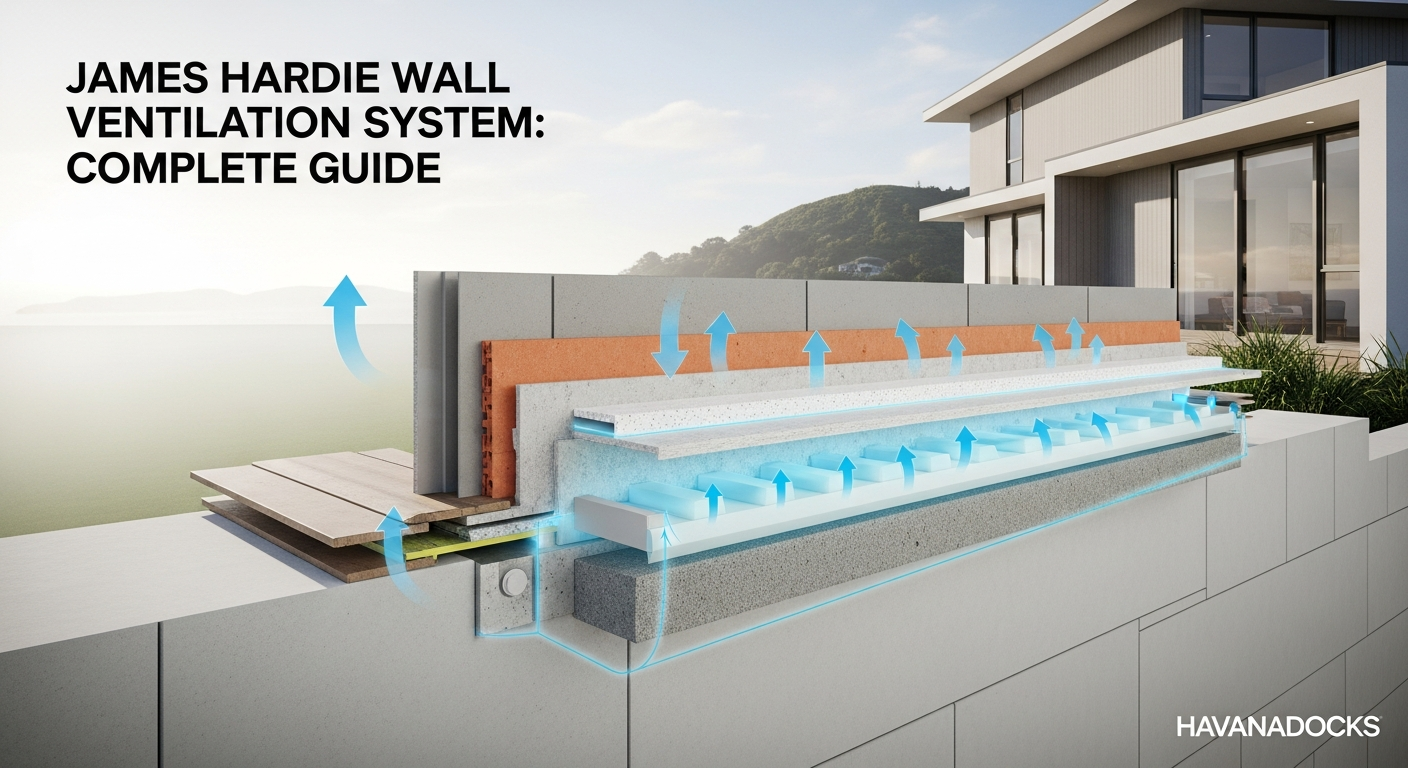

A ventilated wall assembly, often referred to as a rainscreen system, creates a dedicated air gap between the exterior cladding and the water-resistant barrier (WRB). This gap serves two primary functions: it provides a clear drainage path for any bulk water that gets behind the cladding, and it promotes continuous airflow that helps to dry out any residual moisture. By actively managing moisture, a ventilated wall protects the structural framing, maintains the effectiveness of insulation, and contributes to better indoor air quality, making it a non-negotiable feature in high-performance construction.

Understanding the James Hardie Wall Ventilation System

The James Hardie system is not a single product but an integrated suite of components designed to create a pressure-equalized rainscreen cavity. It is engineered to work seamlessly with their renowned fiber cement cladding products, providing a complete, tested, and warranted solution for managing moisture. This approach ensures that every part of the assembly functions in harmony to protect the building envelope.

This system is meticulously designed to manage water and vapor, providing a robust defense against the elements. The core principle is to create a controlled environment behind the cladding where air can circulate freely, carrying away moisture before it can cause damage. Adherence to this james hardie wall ventilation system guide is crucial for achieving optimal performance and longevity for the building’s exterior.

The Science Behind the System: Rainscreen Principles

The effectiveness of the James Hardie system is rooted in the proven science of rainscreen technology. A rainscreen wall separates the cladding from the building’s main wall assembly, creating a capillary break and a ventilation cavity. This design acknowledges that no cladding system is 100% waterproof, especially at joints, corners, and penetrations.

The air cavity behind the cladding serves as a critical buffer zone. When wind-driven rain hits the building, the pressure in the cavity equalizes with the outside air pressure, which significantly reduces the forces driving water through any small openings in the cladding. This pressure equalization is a key aspect that makes the rainscreen so effective at preventing water intrusion, a core topic of this james hardie wall ventilation system guide.

Furthermore, the continuous airflow within the cavity facilitates drying through convection. As air enters through vents at the bottom of the wall, it warms slightly, rises, and exits through vents at the top, carrying moisture vapor with it. This constant “breathing” process ensures that the wall assembly remains dry, resilient, and durable over its lifespan.

Key Components of the System

To function correctly, the system relies on several specifically designed components working in unison. Understanding each part is essential for anyone following this james hardie wall ventilation system guide. Each component has a specific role in creating a continuous and effective ventilation and drainage plane.

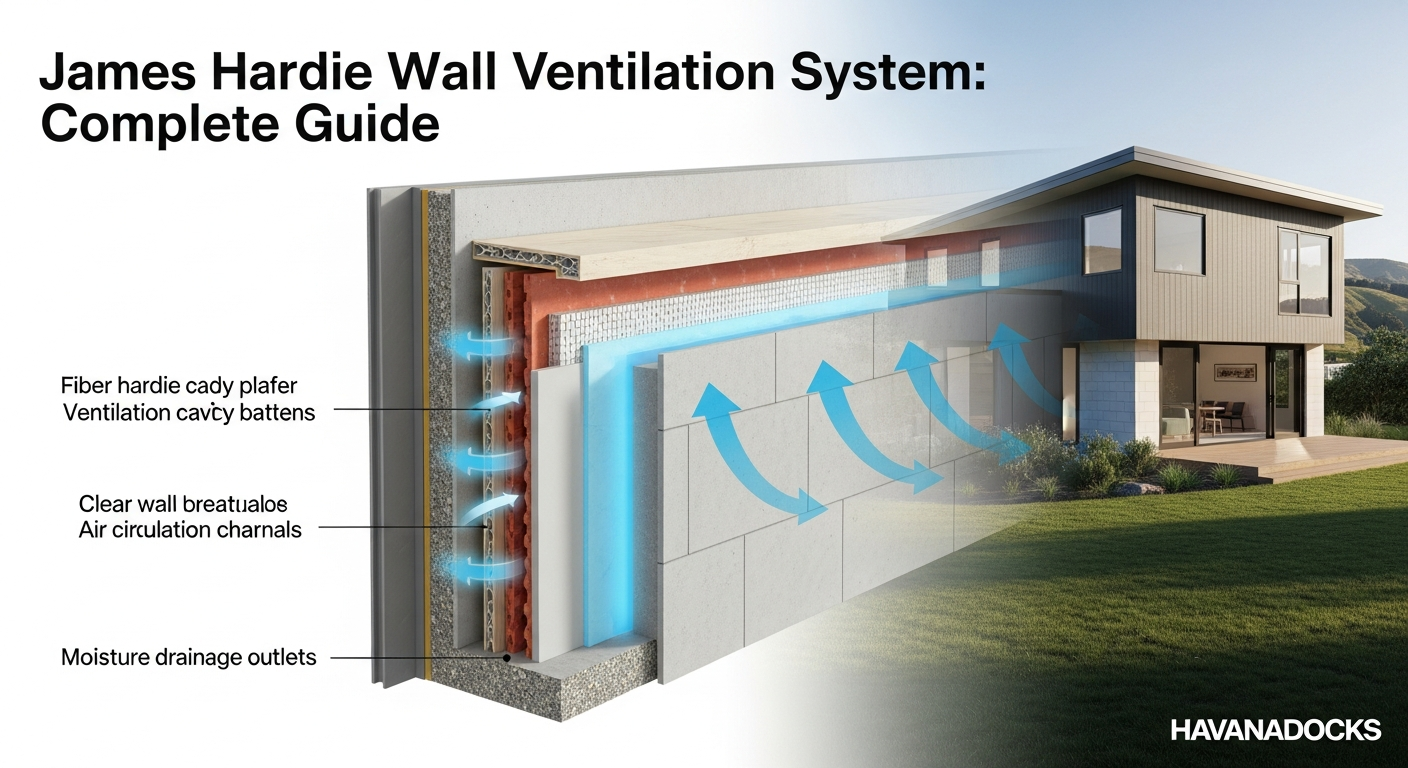

The first line of defense is the HardieWrap™ Weather Barrier. This non-woven, high-performance WRB is installed over the sheathing to resist air and water while allowing moisture vapor to escape from the wall cavity. Its durable construction and proper sealing at seams are foundational to the system’s success.

Next are the battens, which are vertical strips of timber or a compatible material installed over the WRB. These battens create the physical air gap, or ventilation cavity, of a specified depth. The proper sizing and spacing of these battens are critical for ensuring unobstructed airflow and providing a solid fixing point for the cladding, and this james hardie wall ventilation system guide emphasizes their importance.

Finally, a series of specialized ventilation profiles are used to complete the system. These include a starter vent strip at the base of the wall, which allows air to enter while preventing pests and debris from getting into the cavity. Corresponding vents are often used at the top of the wall and over windows and doors to allow the air to exit, completing the convective loop that is so vital to the system’s performance.

Compatibility with James Hardie Cladding Products

A significant advantage of this system is its designed compatibility with James Hardie’s extensive range of fiber cement cladding. Products such as HardiePlank™ Lap Siding, HardiePanel™ Vertical Siding, and the Aspyre Collection® are all intended to be installed over a ventilated rainscreen assembly. Using the complete, specified system ensures that the products perform as intended.

This integration simplifies the design and construction process, as architects and builders can specify a single-source solution for the entire wall envelope. Following the james hardie wall ventilation system guide ensures that warranty requirements are met, providing peace of mind to the building owner. The system is engineered to support the weight and dimensional characteristics of James Hardie siding, guaranteeing a secure and long-lasting installation.

The performance of the cladding itself is also enhanced by the ventilation system. By keeping the back of the siding dry, the system helps to maintain dimensional stability and prolongs the life of the paint or finish. This synergy between the ventilation components and the cladding is a hallmark of the James Hardie approach to building science.

The Benefits of Implementing the James Hardie System

Adopting the complete James Hardie wall ventilation system offers a multitude of benefits that extend far beyond simple weather protection. These advantages contribute to a more durable, healthier, and more efficient building. The investment in a properly ventilated wall assembly pays dividends over the entire life of the structure.

From protecting the capital investment in the building to ensuring the well-being of its occupants, the benefits are comprehensive. This james hardie wall ventilation system guide will now detail these advantages in specific categories. Understanding these benefits helps owners and developers make informed decisions about building envelope design.

Enhancing Building Durability and Longevity

The primary benefit of the system is its profound impact on the durability of the building structure. By systematically managing and removing moisture, it directly combats the root causes of material degradation. This protection is arguably the most critical function detailed in this james hardie wall ventilation system guide.

Wood or steel framing is protected from the constant presence of moisture that leads to rot and corrosion. Insulation maintains its specified R-value because it stays dry, as wet insulation is significantly less effective. The sheathing behind the WRB is also shielded from water damage, preserving its structural integrity for decades.

This proactive approach to moisture management means the building is more resilient against harsh weather conditions. It reduces the likelihood of costly repairs related to water damage down the line. Ultimately, a building equipped with this system is a building that is built to last. A key point of this james hardie wall ventilation system guide is that durability is designed, not accidental.

Improving Indoor Air Quality and Energy Efficiency

A dry wall is a healthy wall, which translates directly to a healthier indoor environment. By preventing the conditions necessary for mold and mildew growth within the wall cavity, the James Hardie system helps to eliminate a major source of indoor air pollutants. Mold spores can contribute to allergies, asthma, and other respiratory issues, so preventing their growth is paramount for occupant health.

Energy efficiency also sees a significant boost. As mentioned, dry insulation performs better, reducing the energy required for heating and cooling the building. Furthermore, the air cavity in the rainscreen system can act as a thermal break, reducing heat transfer through the wall assembly.

During hot summer months, the ventilated cavity allows heat absorbed by the cladding to dissipate before it reaches the interior, reducing the load on air conditioning systems. In cooler climates, it helps to keep the building’s thermal envelope dry and efficient. This focus on performance is a central theme in our james hardie wall ventilation system guide.

Moisture Management and Mold Prevention

Delving deeper into moisture control, the system addresses water in all its forms. It effectively drains away bulk rainwater that penetrates the cladding, which is the first and most critical step. This is a topic that this james hardie wall ventilation system guide cannot overstate.

Beyond bulk water, the system manages interstitial condensation. This occurs when warm, moist air from inside the building travels through the wall assembly and cools, causing water vapor to condense into liquid. The continuous airflow in the ventilation cavity helps to dry out this condensation before it can accumulate and cause damage, a crucial function for buildings in mixed or cold climates.

This robust, multi-faceted approach to moisture management is what makes the system so effective at preventing mold. By removing the key ingredient for mold growth—water—it provides a passive and permanent solution to a pervasive problem in construction. The james hardie wall ventilation system guide provides the framework for achieving this.

Thermal Performance and Cost Savings

The long-term financial benefits of improved thermal performance are substantial. A building that requires less energy to heat and cool will have significantly lower utility bills over its lifespan. This james hardie wall ventilation system guide considers these operational savings a key benefit.

The initial investment in a ventilated rainscreen system is offset by these ongoing savings. Moreover, the improved durability it provides reduces maintenance and repair costs, further enhancing the building’s life-cycle value. This makes the James Hardie system a financially sound choice for both homeowners and commercial property managers.

By creating a more energy-efficient and resilient building, property values are also enhanced. Buildings that can demonstrate high-performance features are more attractive on the market. This comprehensive james hardie wall ventilation system guide shows how the system contributes directly to this value.

Installation Best Practices: A Step-by-Step Overview

Proper installation is absolutely critical to the performance of the James Hardie wall ventilation system. Even the best-designed components will fail if not installed according to the manufacturer’s specifications. This section of the james hardie wall ventilation system guide provides a general overview of the key steps and best practices.

It is imperative that installers are thoroughly familiar with the specific installation instructions provided by James Hardie for their region, as details may vary. These instructions should always be considered the primary source of information. The following steps are intended to provide a foundational understanding of the process.

Step 1: Substrate Preparation

The process begins with ensuring the wall sheathing is structurally sound, clean, and flat. Any significant irregularities in the wall surface should be corrected before proceeding. This initial step is fundamental to a successful outcome, as this james hardie wall ventilation system guide advises.

Step 2: Installing the HardieWrap™ Weather Barrier

The WRB is installed over the sheathing, starting from the bottom and working upwards. Each course should overlap the one below it in a shingle-lap fashion to ensure water drains down and away. All vertical and horizontal seams must be taped with the specified Hardie™ seam tape to create a continuous air and water barrier.

Careful attention must be paid to detailing around window and door openings. The WRB should be properly integrated with flashings at these locations to create a seamless, waterproof seal. The thoroughness of this step is emphasized throughout many a james hardie wall ventilation system guide.

Step 3: Laying Out and Installing Battens

Vertical battens are then installed over the WRB, aligned with the wall studs. The spacing of the battens is determined by the James Hardie cladding being used and local building code requirements, typically at 16 or 24 inches on center. The thickness of the battens defines the depth of the ventilation cavity and must be consistent.

Battens must be securely fastened through the sheathing and into the studs using corrosion-resistant fasteners of the appropriate length. It is crucial to ensure the battens are plumb and create a true plane for the siding installation. Following this part of the james hardie wall ventilation system guide is vital for a flat, visually appealing final wall.

Step 4: Installing Ventilation Profiles

The starter vent strip is installed along the base of the wall, fixed to the bottom of the battens. This profile must be continuous to provide an effective pest screen while allowing for maximum airflow into the cavity. Any gaps or misalignments can compromise the system’s integrity.

Similarly, ventilation profiles are installed at the top of the wall, below soffits, and over the heads of windows and doors. These details allow the warm, moist air to exit the cavity, completing the convective loop. A complete james hardie wall ventilation system guide will always highlight the importance of these critical transition details.

Step 5: Installing James Hardie Cladding

With the underlying ventilation assembly complete, the James Hardie siding can be installed. The cladding is fastened directly to the battens, not through to the sheathing. This ensures the ventilation cavity remains open and unobstructed.

Installers must use the fasteners specified by James Hardie and follow the required nailing patterns. Clearances must be maintained between the siding and adjacent surfaces like roofs, decks, and hardscaping to prevent moisture wicking. Every installation detail in the james hardie wall ventilation system guide is designed to maximize performance.

Step 6: Detailing and Finishing

The final step involves installing trim, corner boards, and properly sealing any remaining gaps around penetrations with a compatible, high-quality sealant. All finishing touches should be completed according to James Hardie’s specifications to ensure a weathertight and aesthetically pleasing finish. This final attention to detail is what distinguishes a professional installation when using this james hardie wall ventilation system guide.

Working with a certified installer who understands the nuances of this system is highly recommended. Their expertise ensures that every component is installed correctly, guaranteeing the long-term performance and warranty coverage of the wall assembly. The purpose of a james hardie wall ventilation system guide like this is to inform, but professional execution is key.

Conclusion: Investing in a Healthier Building Envelope

In conclusion, the integrity of a building’s wall assembly is paramount to its longevity, efficiency, and the health of its occupants. The challenges of modern, airtight construction demand sophisticated solutions for managing moisture. The james hardie wall ventilation system guide presented here demonstrates a comprehensive, engineered approach to creating a high-performance building envelope.

By embracing the proven principles of rainscreen technology and integrating a suite of purpose-built components, the system offers robust protection against water intrusion and condensation. The benefits are clear: enhanced durability, improved indoor air quality, greater energy efficiency, and long-term cost savings. It transforms the wall from a simple barrier into a dynamic, breathing system.

Ultimately, choosing to implement the James Hardie wall ventilation system is an investment in the fundamental health of the structure. It is a commitment to building better, more resilient, and more sustainable buildings that will stand the test of time. For any architect, builder, or owner focused on quality and performance, following this james hardie wall ventilation system guide is a definitive step toward achieving a superior building envelope.