Understanding Modern Fire-Resistant Wall Systems

Understanding Modern Fire-Resistant Wall Systems – Elena traced the skyline with her finger, her reflection faint against the conference room window. Below, the city was a tapestry of glass and steel, a testament to human ambition. Her ambition, the Solstice Tower, was still just a blueprint and a dream, but one detail consumed her thoughts more than any other: safety.

She wasn’t just designing another skyscraper; she was crafting a vertical community where thousands would live and work. The haunting images of historical fires were a constant reminder of her responsibility. Her mission became to understand and implement the absolute best in modern fire resistant wall system technology, ensuring her creation would be a bastion of safety, not a monument to risk.

The Unseen Guardian: The Evolution of Fire Resistance

Elena’s journey into safety began with a look into the past. She discovered that the concept of fire resistance was as old as cities themselves. Ancient Romans used concrete and stone, recognizing their inherent ability to contain fires.

The Industrial Revolution, however, brought new materials and denser cities, creating unprecedented fire hazards. Catastrophic events like the Great Fire of London and the Chicago Fire of 1871 became brutal teachers. These tragedies forged the foundations of modern building codes, shifting the focus from simply rebuilding to building with resilience in mind.

From these ashes, the science of fire safety engineering was born. Early efforts were crude, relying on thick masonry and simple compartmentalization. Today, the evolution of fire resistant wall system technology has transformed these basic principles into a sophisticated, multi-layered science, a quiet guardian integrated into the very bones of our buildings.

Core Principles of Modern Fire-Resistant Walls

To build the future, Elena knew she had to master the fundamentals. She delved into the core principles that govern how modern structures withstand the ravages of a fire. It wasn’t about making walls “fireproof,” an impossible term, but about making them predictably and reliably resistant for a specific duration.

These principles form a three-pronged strategy: contain the fire, starve it of what it needs to grow, and provide a clear, quantifiable measure of a wall’s performance. The success of any fire resistant wall system technology hinges on how well it executes these fundamental concepts. Elena understood that these weren’t just lines in a building code; they were the grammar of survival.

Compartmentation: The Art of Containment

The first and most critical principle Elena studied was compartmentation. The concept is elegantly simple: divide a large building into smaller, sealed-off compartments using fire-rated walls, floors, and ceilings. This strategy prevents a fire from spreading rapidly throughout the entire structure.

These compartments act like watertight bulkheads on a ship, isolating the damage to one area. This containment gives occupants precious time to evacuate and provides firefighters with a more controlled environment to combat the blaze. The effectiveness of this strategy depends entirely on the integrity of the barriers, making the choice of fire resistant wall system technology paramount.

A successful compartmentation strategy means that a fire starting in one apartment or office is held there. It cannot easily breach the walls to reach adjacent units or escape routes. This masterful use of fire resistant wall system technology transforms a building from a single, vulnerable entity into a network of defensible spaces.

The Fire Triangle and How Walls Defeat It

Next, Elena revisited the basic science of combustion: the fire triangle. Fire needs three things to exist: heat, fuel, and an oxidizer (typically oxygen). Remove any one of these elements, and the fire dies.

A fire-resistant wall primarily attacks the “heat” and “fuel” sides of the triangle. It acts as a thermal barrier, slowing the transfer of intense heat from one side to the other. This prevents temperatures in adjacent rooms from rising to the point where new materials, the “fuel,” spontaneously ignite.

Furthermore, by containing the fire, the wall limits its access to fresh oxygen and new fuel sources in other parts of the building. In essence, the core function of a fire resistant wall system technology is to break the chain reaction of a fire. It stands as a physical barrier that systematically starves the fire until it can be extinguished.

Understanding Fire Ratings (F, T, and L Ratings)

Elena found that not all fire-resistant walls are created equal. Their performance is measured and certified through standardized testing, resulting in specific fire ratings. Understanding these ratings was crucial for selecting the right systems for different areas of the Solstice Tower.

The most common rating is the “F” rating, or Flame rating, measured in hours (e.g., 1-hour, 2-hour). This indicates how long a wall assembly can withstand direct exposure to fire before the flames breach the other side. A 2-hour rated wall, for instance, must prevent the passage of fire for at least two hours under test conditions. This metric is a cornerstone of modern fire resistant wall system technology.

The “T” rating, or Temperature rating, is often more stringent. It measures how long it takes for the unexposed side of the wall to heat up by a specific amount. This is vital for protecting escape routes and preventing the auto-ignition of materials on the “safe” side of the wall. Finally, the “L” rating measures air and smoke leakage, a critical factor since smoke inhalation is a leading cause of fire-related fatalities. The thoughtful application of this rated fire resistant wall system technology is what creates a truly safe building.

The Anatomy of a Modern System: Materials and Innovation

From Materials to Mastery: The Evolution of Fire-Resistant Wall System Technology

With a firm grasp of the fundamental principles, Elena’s curiosity naturally turned toward the materials themselves — the very substances that make modern buildings both elegant and safe. What she discovered was a world that had evolved far beyond traditional brick-and-mortar construction. The field of fire-resistant wall system technology has become a pinnacle of engineering innovation, combining material science, performance testing, and architectural design into one unified pursuit: the protection of human life.

Gone are the days when a wall’s fire resistance depended solely on its mass or thickness. Today’s systems represent a fusion of art and science, where every layer, joint, and fastening point contributes to an intelligent whole. It is a story of evolution — from the crude walls of early architecture to the meticulously engineered, performance-verified assemblies that now define the modern built environment.

A Layered Symphony of Strength and Science

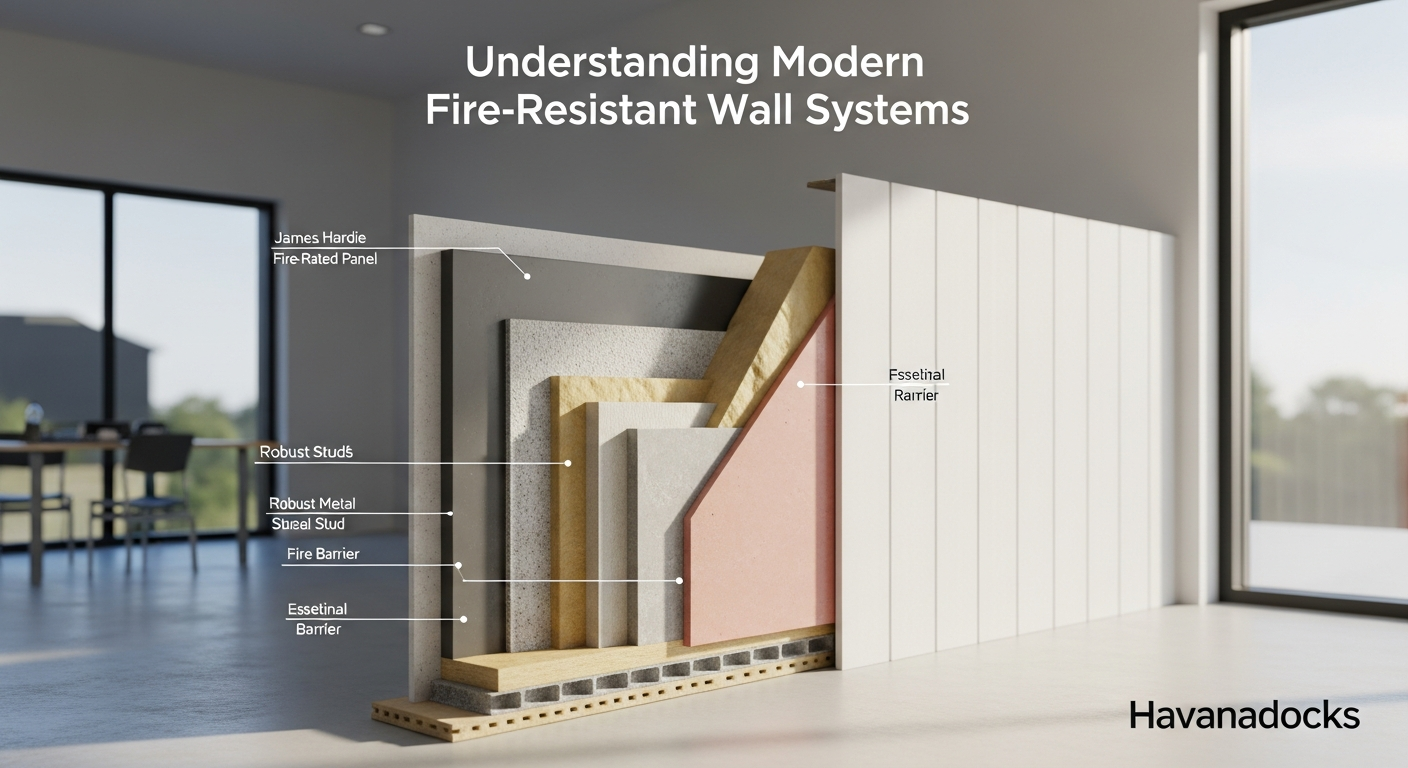

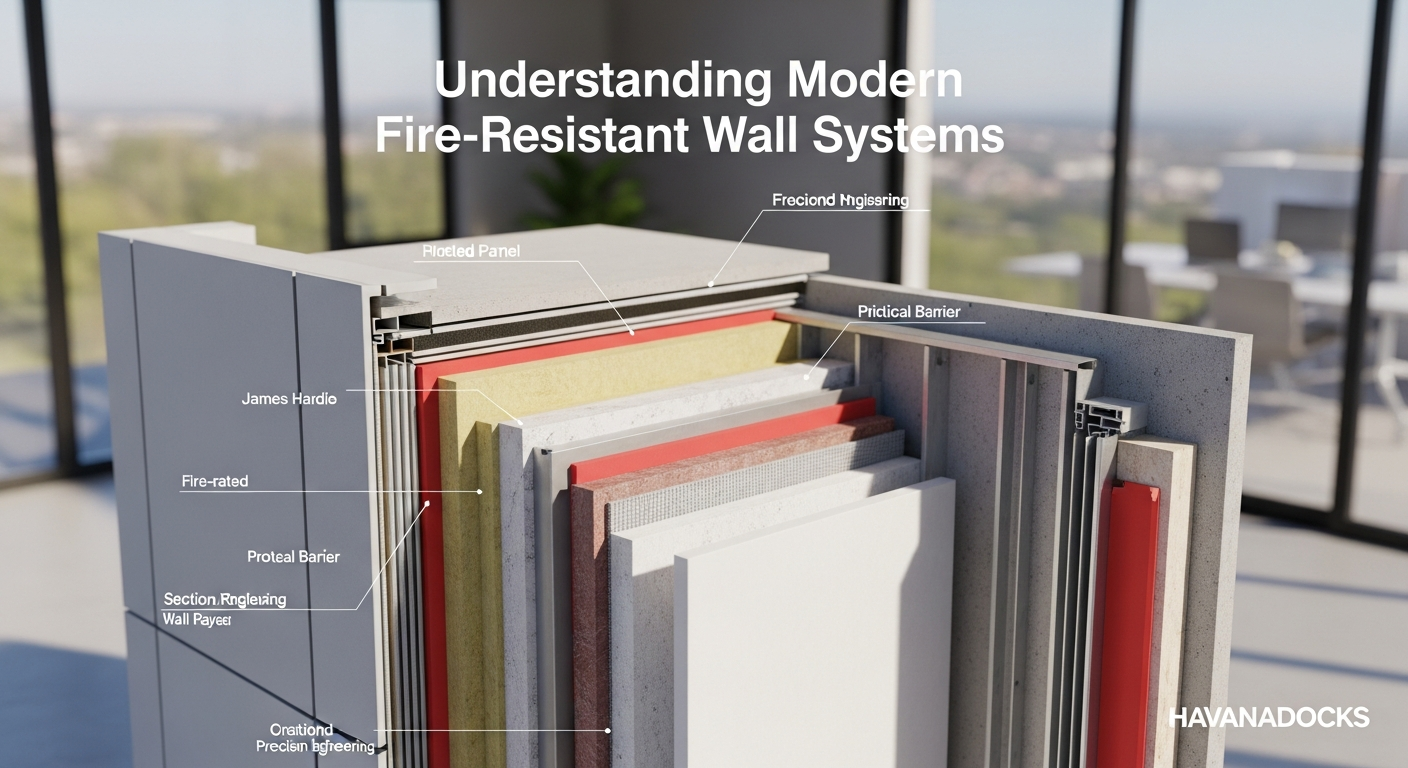

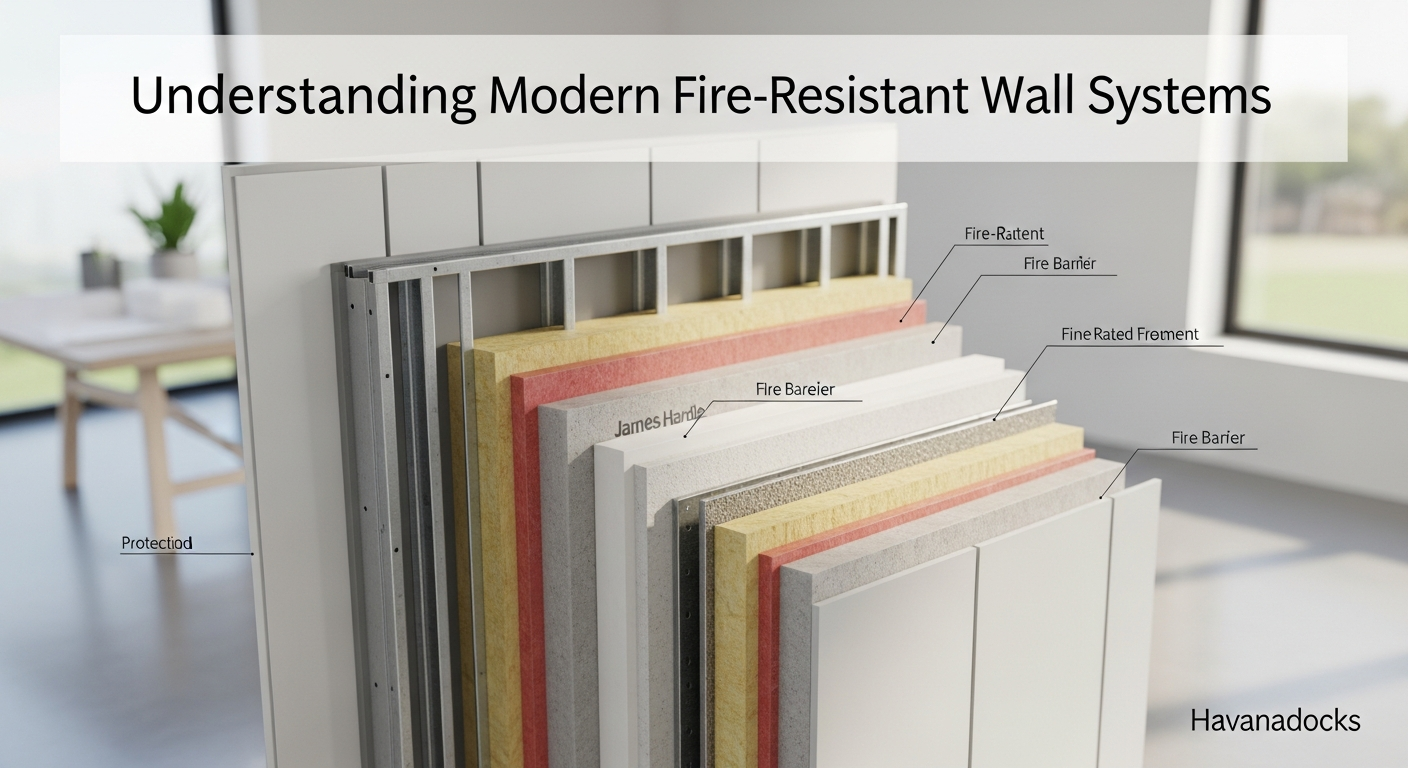

Elena was astonished to learn that a fire-rated wall is rarely a single material. Instead, it’s a precise assembly of components, each playing a vital and interdependent role. These components are designed to perform collectively under the extreme heat and pressure of a fire — much like an orchestra, where the harmony depends on the synchronization of every instrument.

At its core, a modern fire-resistant wall is made up of multiple layers:

-

Structural framing – Typically built from timber or light-gauge steel, this framework provides strength and stability. The choice of material affects not just load-bearing capacity, but also thermal conductivity and fire performance.

-

Fire-rated sheathing or lining – High-performance boards such as fiber cement, fire-grade plasterboard, or calcium silicate sheets form the outer shield. These materials resist ignition, slow heat transfer, and help contain the fire within a designated compartment.

-

Insulation – Layers of non-combustible mineral wool or rockwool are inserted within cavities to absorb heat and maintain temperature control. This insulation prevents fire from spreading between rooms or floors, safeguarding escape routes.

-

Fasteners and jointing systems – Every screw, adhesive, and joint compound must be fire-rated and tested as part of the system. Even minor deviations from the tested configuration can compromise performance.

-

Penetration seals – Pipes, electrical cables, and ducts that pass through the wall are sealed using intumescent collars, wraps, or fire-rated foams, which expand when exposed to heat, closing gaps and preventing the passage of flames and smoke.

Each of these elements is engineered for precision and tested in combination, not in isolation. It’s not enough for a single component to resist fire — the system as a whole must work together under extreme conditions. As Elena’s architect explained, “A fire-rated wall is not a product; it’s a performance promise.”

Beyond the Material: A Systemic Philosophy

For centuries, architects and builders relied on the sheer mass of materials like brick, stone, or concrete to resist fire. While effective to an extent, these traditional methods often came at the cost of design flexibility, increased weight, and slow construction. Modern engineering has revolutionized this approach, replacing brute strength with strategic intelligence.

Today’s fire-resistant wall systems are built on the principle of integration — the idea that multiple specialized materials, when combined, can outperform any single substance alone. The industry no longer seeks one “hero material.” Instead, it focuses on systemic collaboration, where each layer contributes a distinct property: thermal resistance, structural stability, acoustic insulation, or vapor control.

This integrated approach ensures that even as architectural trends evolve — with open layouts, lightweight structures, and extensive glazing — fire safety remains uncompromised. In essence, form and function no longer need to be at odds. Builders can achieve sleek, modern aesthetics without sacrificing the invisible strength that lies within the walls.

From Laboratory to Living Space: The Science Behin

Beyond Simple Drywall: The Role of Gypsum

Elena’s investigation started with the most ubiquitous material in modern interior construction: gypsum board, or drywall. She quickly learned that the standard drywall in a home is very different from the specialized panels used in commercial high-rises. The secret to gypsum’s fire resistance lies in its chemical composition.

Gypsum is calcium sulfate dihydrate (CaSO₄·2H₂O), meaning it contains chemically bound water molecules. When exposed to high heat, a process called calcination occurs, where this water is released as steam. This process absorbs a significant amount of thermal energy, dramatically slowing the transfer of heat through the wall.

Specialized “Type X” and “Type C” gypsum boards enhance this natural ability. Type X has a denser core with glass fibers for added structural integrity in a fire. Type C contains additives like vermiculite that help the core maintain its structure even longer as the gypsum dehydrates. This advancement in gypsum C is a foundational piece of fire resistant wall system technology.

For the Solstice Tower’s residential units and office spaces, Elena specified layered assemblies of Type C gypsum. This proven and cost-effective fire resistant wall system technology would form the primary line of defense for compartmentation. It was a perfect blend of performance and practicality.

Advanced Materials and Composite Systems

While gypsum formed the foundation, Elena knew that critical areas like elevator shafts, stairwells, and mechanical rooms required even more robust solutions. Her research led her into the world of advanced materials and composites. This is where the cutting edge of fire resistant wall system technology truly shines.

These systems move beyond the passive resistance of gypsum into sophisticated, high-performance materials. They include mineral fiber boards, cementitious panels, and advanced polymer composites. Many of these modern materials offer superior structural stability at extreme temperatures and can achieve higher fire ratings with less thickness and weight, a significant advantage in skyscraper design.

The development of these advanced materials represents a paradigm shift. Engineers are no longer limited to heavy, traditional materials. They can now select a specific fire resistant wall system technology tailored to the unique demands of each part of a building, optimizing for safety, space, and efficiency.

Intumescent Coatings and Panels

Elena was particularly captivated by intumescent technology. These remarkable materials are “smart” in their response to heat. At normal temperatures, they are inert, often appearing as a thin layer of paint or a solid panel.

When exposed to the heat of a fire, however, a chemical reaction is triggered. The intumescent material swells dramatically, expanding to many times its original thickness. This expanded layer, called a char, is a highly effective insulator that protects the underlying structure from heat and flame. The sophistication of this fire resistant wall system technology is truly remarkable.

Elena decided to specify intumescent coatings for exposed structural steel elements and intumescent sealants around all pipe and cable penetrations. These products would seal the small gaps that could otherwise compromise a fire-rated wall. This active response system provided an intelligent and dynamic layer of protection, a crucial component of a comprehensive fire resistant wall system technology.

Concrete and Masonry Innovations

Elena also explored the evolution of the oldest fire-resistant materials: concrete and masonry. While traditional concrete blocks are effective, modern innovations have made them even better. She discovered materials like Autoclaved Aerated Concrete (AAC) and Insulated Concrete Forms (ICFs).

AAC is a lightweight, precast concrete material containing countless tiny air pockets. These pockets make it an excellent thermal insulator, giving it a very high fire-resistance rating for its weight. Using AAC for certain interior partitions would reduce the building’s overall structural load without sacrificing safety. It is a fantastic example of evolving fire resistant wall system technology.

Insulated Concrete Forms (ICFs) consist of hollow, interlocking foam blocks that are stacked and then filled with reinforced concrete. The foam forms provide permanent insulation, but specialized fire-resistant grades ensure the assembly achieves high fire ratings. Elena earmarked ICFs for the core walls of the Solstice Tower, providing exceptional structural and fire-resistant performance in a single, efficient system. This modern take on a classic material is a powerful form of fire resistant wall system technology.

The Human Element: Installation, Inspection, and Maintenance

As Elena finalized her material selections, she met with the future construction manager, a seasoned veteran named Marcus. He commended her thorough research but offered a crucial piece of wisdom. “Elena,” he said, gesturing to a complex blueprint, “the most advanced fire resistant wall system technology in the world is only as good as the hands that install it.”

Marcus explained that a tiny, unsealed gap around a pipe or an incorrect screw pattern in a gypsum board assembly could cause a catastrophic failure. A 2-hour rated wall could fail in 20 minutes due to improper installation. Every penetration for plumbing, wiring, and HVAC must be meticulously sealed with approved firestopping products.

This conversation solidified a new focus for Elena: quality control. She realized her job didn’t end with the design. It had to extend to a rigorous process of inspection and verification during construction. The integrity of the building’s fire resistant wall system technology depended on it.

She worked with Marcus to develop a multi-stage inspection plan. This included training for installation crews, third-party inspections of fire-rated assemblies before they were concealed, and detailed documentation of all firestopping measures. The investment in this fire resistant wall system technology had to be protected by a parallel investment in human expertise and diligence.

Furthermore, they planned for the building’s future. A maintenance manual would be created for the facilities management team, detailing the importance of maintaining the integrity of fire-rated walls. Any future renovations or repairs would have to be done to the same high standards, ensuring the building’s safety features remained intact for its entire lifespan. The lifecycle of the fire resistant wall system technology was as important as its initial installation.

Conclusion: Building a Safer Tomorrow

Months later, Elena stood at the groundbreaking ceremony for the Solstice Tower. The blueprints were no longer just paper; they were a promise. A promise of a safe, resilient, and forward-thinking structure.

Her deep dive into the world of fire safety had transformed her as an architect. She now saw buildings not just as static objects, but as dynamic systems designed to protect human life. From the principles of compartmentation to the chemistry of gypsum and the intelligence of intumescent coatings, every decision was informed by this new understanding. The project was a showcase of modern fire resistant wall system technology.

The Solstice Tower would be built with more than just steel and glass. It would be constructed with layers of carefully chosen materials and science-backed systems. Its unseen guardians—the advanced walls, the sealed penetrations, the meticulously inspected assemblies—would stand ready. Elena’s journey affirmed that the most important feature of any building is the safety of those within, a legacy built upon the quiet, unwavering strength of modern fire resistant wall system technology.