What Is a Fire-Rated Wall System? Understanding the Basics

What Is a Fire-Rated Wall System? Understanding the Basics – In the realm of building construction and safety, few elements are as critical as those designed to protect occupants from the ravages of fire. These measures are often unseen, integrated seamlessly into the structure of a building, yet they stand as the first line of defense. They are a fundamental component of a strategy known as passive fire protection.

At the heart of this strategy lies the fire-rated wall, a meticulously engineered barrier designed to contain a fire and halt its spread. It provides precious minutes for evacuation and for first responders to arrive. This article provides a comprehensive overview of a fire rated wall system explained for architects, builders, and safety professionals alike.

The Core Concept of Passive Fire Protection

Passive fire protection involves using building components to control and slow the spread of fire without any active response. It is built into the very fabric of a structure, working silently to compartmentalize a building. This contrasts with active fire protection, which includes systems like sprinklers and alarms that require activation to function.

The primary goal of passive systems is compartmentalization, which means dividing a building into smaller, sealed sections. A fire-rated wall system is the primary tool for achieving this objective effectively. The What Is a Fire-Rated Wall System? Understanding the Basics here is designed to contain fire and smoke within the compartment of origin for a specified period.

This containment strategy saves lives by maintaining clear escape routes and protecting structural integrity. It also significantly reduces property damage by limiting the fire’s reach. A well-designed passive fire protection plan is a non-negotiable aspect of modern building codes.

What Constitutes a Fire-Rated Wall System?

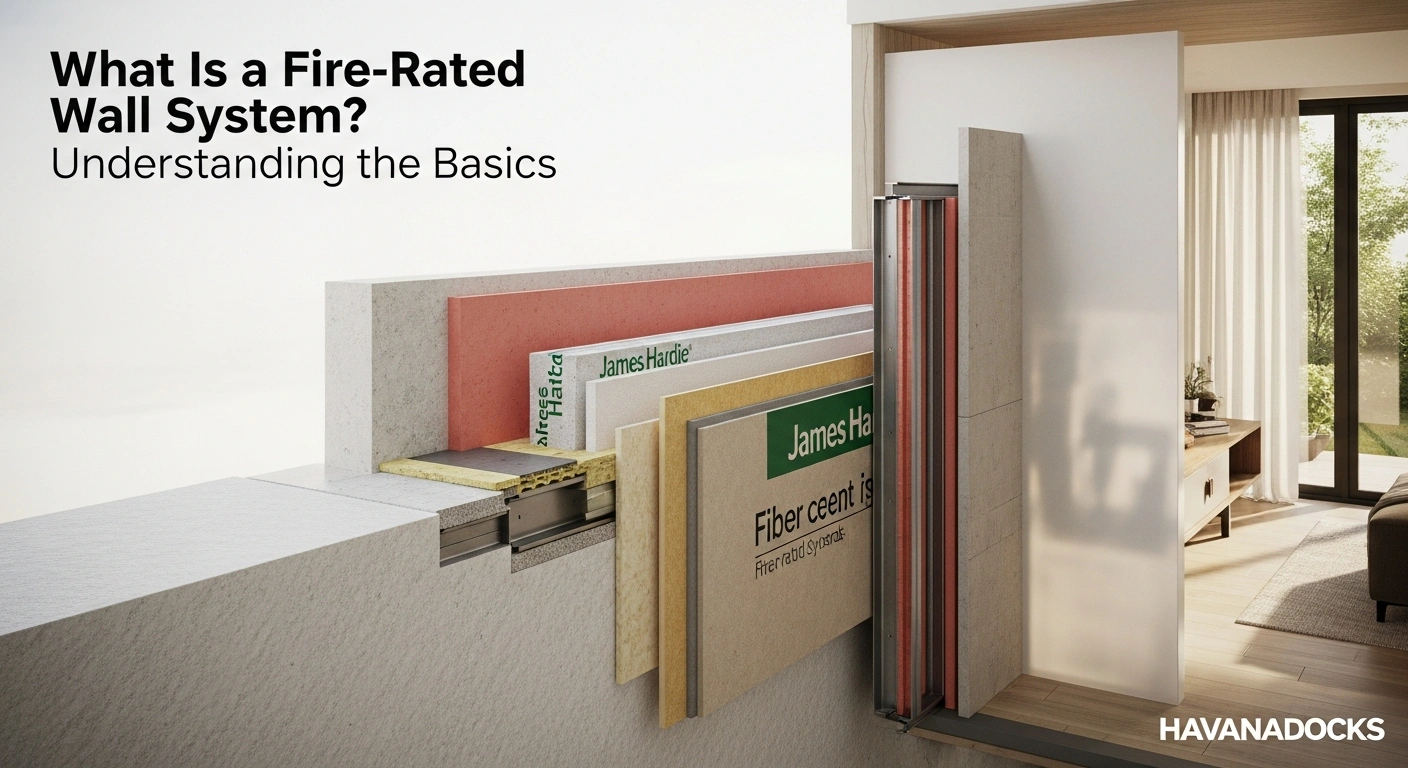

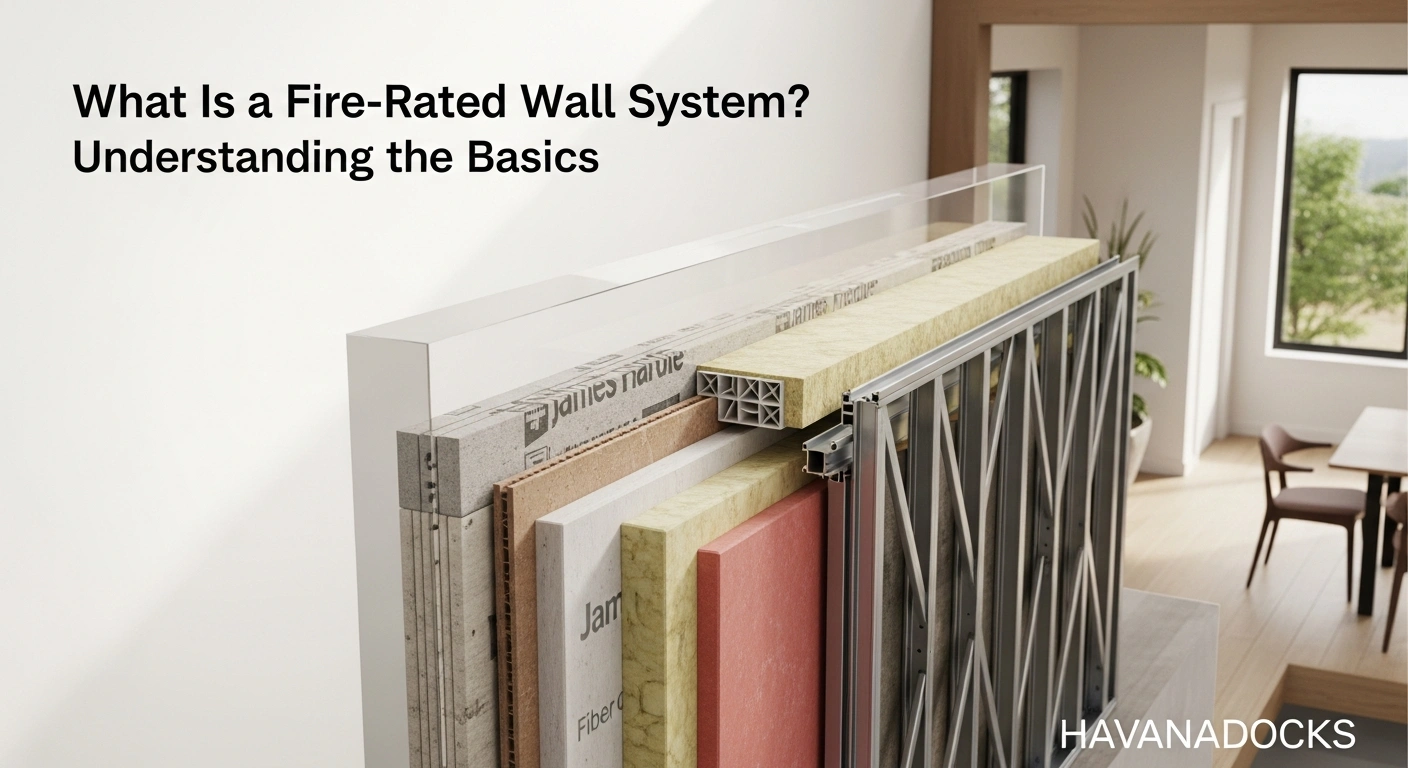

It is a common misconception that a fire-rated wall is simply a special type of drywall. In reality, it is a complete assembly of components that must work in unison to achieve its fire-resistance rating. The failure of even one component can compromise the entire barrier.

This assembly includes the structural framing, specific types of sheathing like fire-rated gypsum board, insulation, and specialized finishing components. It also accounts for fasteners, joint compounds, and sealants used to close gaps. For a complete fire rated wall system explained properly, every single element must be considered part of the whole.

Furthermore, any openings or penetrations for pipes, ducts, or wiring must be protected with approved firestopping materials. These materials are designed to restore the wall’s fire-resistance rating where it has been breached. This holistic view is crucial for both design and installation.

Understanding Fire-Resistance Ratings

The performance of a fire-rated wall is quantified by its fire-resistance rating. This rating is expressed in hours, such as 1-hour, 2-hour, or 3-hour. This value indicates the duration for which the wall assembly can withstand a standard fire test while maintaining its structural function.

The rating is not just about preventing flames from passing through the wall. It also measures the wall’s ability to limit the temperature rise on the non-fire side. This is critical to prevent the ignition of combustible materials in adjacent spaces. To have a fire rated wall system explained thoroughly, one must understand these dual criteria.

These ratings are determined through rigorous testing protocols established by organizations like ASTM International (ASTM E119) and Underwriters Laboratories (UL 263). During these tests, a sample wall is subjected to controlled fire conditions that follow a standard time-temperature curve. The assembly must then withstand the force of a fire hose stream test, simulating the impact of firefighting efforts.

The Role of Materials in Fire Resistance

The materials chosen for a fire-rated wall are the foundation of its performance. Gypsum board is the most common sheathing material due to its inherent fire-resistant properties. The core of a standard gypsum panel is composed of gypsum, which is chemically known as calcium sulfate dihydrate (CaSO₄·2H₂O).

When exposed to high heat, this water is slowly released as steam, a process called calcination. This process absorbs significant heat energy, effectively slowing the temperature rise on the opposite side of the wall. The fire rated wall system explained by material science highlights the importance of this chemical reaction.

For enhanced fire resistance, specialized gypsum boards are used. Type X gypsum board contains glass fibers mixed into the core to improve its integrity during a fire. Type C gypsum board offers even greater fire resistance, as it includes vermiculite and other additives that help the core stay in place even after the water has turned to steam.

Beyond the Wallboard: The Importance of Assembly

The effectiveness of a fire-rated wall depends on the entire assembly, not just the gypsum board. The structural framing, whether wood or steel, plays a vital role. Steel studs are non-combustible, while wood studs must often be of a certain dimension or be treated with fire retardants to be used in rated assemblies.

Fasteners, such as screws and nails, are equally important. Their type, length, and spacing are precisely specified in the tested assembly’s design. Incorrect fastener patterns can lead to premature failure of the gypsum panels under fire conditions.

Moreover, every joint and penetration must be meticulously sealed. Fire-rated caulk, sealants, and putties are used to fill gaps around pipes, conduits, and electrical boxes. For larger openings like ducts, fire dampers are installed to close automatically in the event of a fire, completing the fire rated wall system explained from a holistic perspective.

Key Components of a Fire-Rated Wall System Explained in Detail

To truly appreciate the engineering behind these assemblies, it is necessary to examine each component’s specific role. The synergy between framing, sheathing, insulation, and firestopping is what creates a reliable barrier against fire. Each part is selected and installed based on proven performance in standardized tests.

The design of a fire-rated wall is not arbitrary; it must precisely match a design listed by a recognized testing agency like UL or Gypsum Association. Any deviation from the specified materials or construction methods voids the rating. The details of a fire rated wall system explained in testing literature are prescriptive for this reason.

This section will delve deeper into the primary components that constitute a robust and compliant fire-rated wall. Understanding these elements is essential for architects specifying the systems and contractors responsible for building them. The precision of the assembly is paramount to its life-saving function.

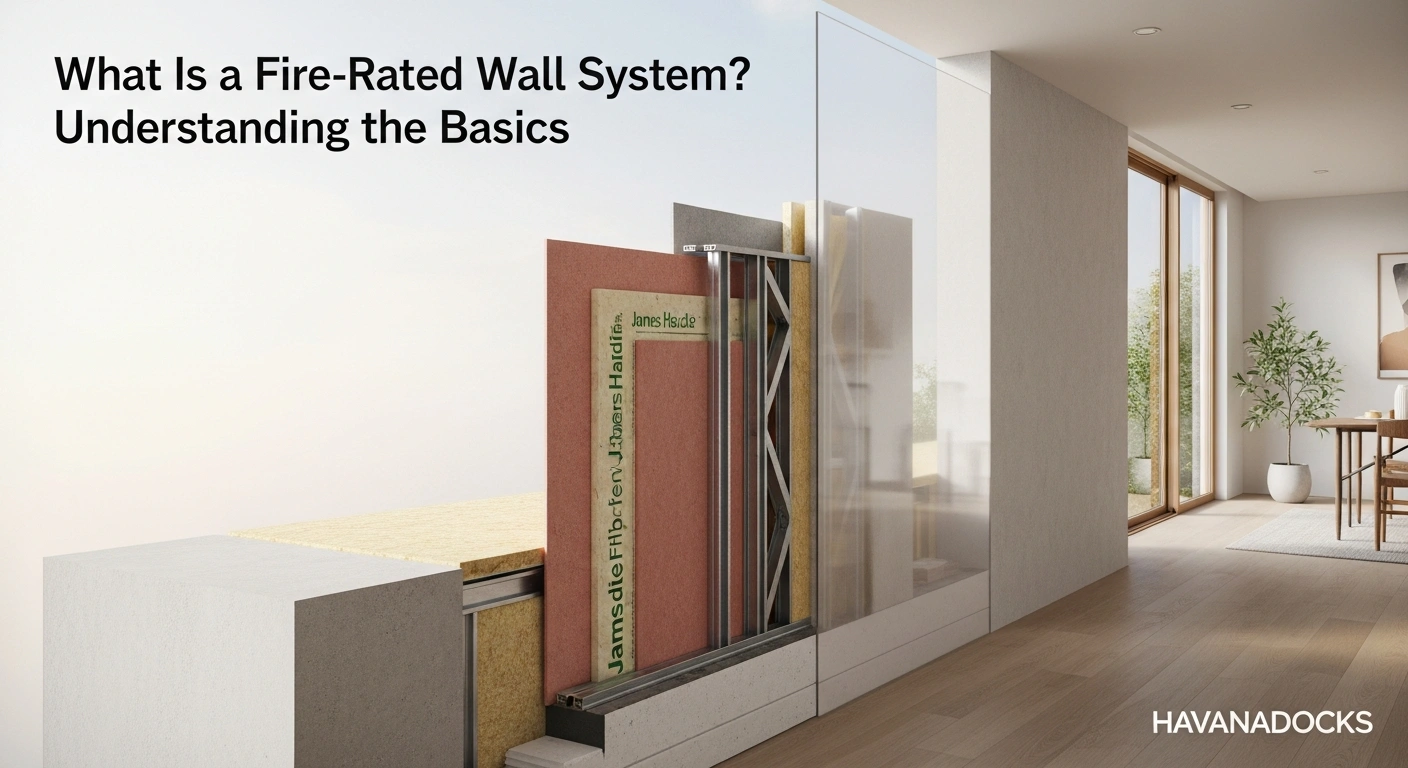

Framing and Structural Support

The framing serves as the skeleton of the fire-rated wall, providing the structural support for the sheathing and other components. The choice between steel and wood studs significantly impacts the design of the assembly. Both materials can be used to construct fire-rated walls, but their behavior in a fire differs.

Steel studs are non-combustible and do not contribute fuel to a fire. However, steel can lose its strength at high temperatures, potentially leading to structural failure if not properly protected. The gauge (thickness) and depth of the steel studs are critical specifications in a rated assembly. A fire rated wall system explained by engineers always includes these detailed framing specifications.

Wood studs are combustible, but they char at a slow and predictable rate. This char layer acts as an insulator, protecting the core of the stud and allowing it to retain some structural capacity for a period. For higher fire ratings, larger dimension lumber or multiple layers of gypsum board may be required to protect the wood framing.

Sheathing and Insulation

The sheathing is the primary barrier that confronts the fire, and its performance is central to the wall’s rating. Insulation, while often installed for thermal or acoustic reasons, also plays an important part in many fire-rated designs. Together, they manage the intense heat of a fire.

These two components are responsible for satisfying the two main criteria of a fire-resistance test: preventing the passage of flames and limiting the transfer of heat. The selection and installation of these materials must be done with extreme care. Here, the fire rated wall system explained in detail reveals the science behind fire containment.

The following sections will break down the specific types of sheathing and insulation commonly used. Each has unique properties that contribute to the overall effectiveness of the wall system. A proper understanding is key to successful implementation.

Gypsum Board Varieties

As mentioned, gypsum board is the cornerstone of most fire-rated walls. Type X gypsum board, typically 5/8-inch thick, is the standard for many 1-hour rated walls. Its core is reinforced with glass fibers that enhance its cohesion and prevent it from crumbling when exposed to fire.

For 2-hour ratings or higher, multiple layers of Type X board are often required. Alternatively, Type C or Type X Shaftliner panels can be used. Type C board contains vermiculite and a higher density of glass fibers, which causes it to shrink less and maintain its integrity for longer periods at high temperatures. The science of a fire rated wall system explained through its materials shows continuous innovation.

Shaftliner panels are thicker panels (typically 1-inch thick) used in fire-rated shaft walls for elevators and utility chases. These systems are designed to be constructed from one side, a common requirement in tight spaces. The choice of gypsum board must always correspond to the specific listed assembly.

Insulation’s Contribution to Fire Safety

Insulation within a fire-rated wall cavity serves several functions. Its primary role is to slow the transfer of heat through the wall assembly. This helps keep the temperature on the non-fire side below the critical limit for a longer duration.

Mineral wool (also known as rock wool) is a popular choice for fire-rated assemblies. It is created by melting rock and spinning it into fibers, resulting in a non-combustible material with an extremely high melting point, often exceeding 2,000°F (1,093°C). This makes it an excellent barrier to heat. The value of a fire rated wall system explained with mineral wool is evident in its superior performance.

Fiberglass insulation is also non-combustible and can be used in many fire-rated wall designs. While it has a lower melting point than mineral wool, it still contributes to the overall rating by filling the cavity and preventing convective heat transfer. The presence and type of insulation are always specified in the tested assembly details.

Installation and Maintenance: Ensuring Compliance and Effectiveness

A perfectly designed fire-rated wall is useless if it is not installed correctly. The contractor’s adherence to the specified design is not just a matter of quality control; it is a critical life safety requirement. Every step, from stud spacing to screw depth, must be executed with precision.

Common installation errors include using the wrong type or number of fasteners, leaving gaps at the top or bottom of the wall, or improperly sealing joints. Another frequent and dangerous mistake is the incorrect handling of penetrations. The fire rated wall system explained by installation guides must be followed to the letter.

Building inspectors play a crucial role in verifying that these systems are built in compliance with codes and the listed design. The integrity of the wall depends on meticulous workmanship. This is why a fire rated wall system explained during pre-construction meetings is so vital.

Once installed, a fire-rated wall requires ongoing maintenance to ensure its continued effectiveness. Over the life of a building, new pipes, wires, or ducts are often added, creating new penetrations in these critical barriers. Each new opening must be properly firestopped.

Regular inspections should be conducted to check for damage to the wall, such as holes or cracks in the gypsum board. Any damage must be repaired using approved methods that restore the original fire rating. The fire rated wall system explained to facility managers should emphasize this life-cycle responsibility.

The responsibility for maintaining the integrity of fire-rated assemblies extends throughout the building’s lifespan. A proactive approach to maintenance ensures that the passive fire protection system remains ready to perform its life-saving function at all times. A fire rated wall system explained is not just about construction, but about perpetual readiness.

Conclusion: The Indispensable Role of Fire-Rated Walls

In conclusion, a fire-rated wall is far more than an ordinary partition; it is a life-saving engineered system. Its function is to create barriers of resilience within a building, containing a fire at its source and providing a safe pathway for occupants to escape. This is the core purpose of a fire rated wall system explained.

The effectiveness of these walls hinges on the correct design, the use of specified materials, and meticulous installation. From the steel studs and Type X gypsum to the fire-rated sealant around a pipe, every component must work together as part of a tested and certified assembly. Understanding the fire rated wall system explained in its entirety is crucial.

Ultimately, these systems are a silent yet powerful testament to the importance of building codes and safety engineering. They protect lives and property by fundamentally controlling how a fire behaves within a structure. Proper implementation and maintenance of fire-rated walls are a non-negotiable cornerstone of modern, safe construction.